- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

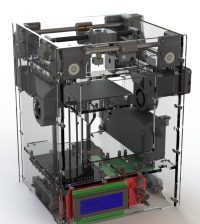

OpenSLS reported being on a Good Progress

You may already know the project: OpenSLS looks in good shape and in a recent post on 3Dprint.com, you can read here, they’ve been covering late progress.

Worth a read!

For those not familiar with OpenSLS:

OpenSLS is a platform for exploring the selective laser sintering process and a functioning prototype SLS 3D printer capable of fabricating objects in a variety of materials. It was developed at the Advanced Manufacturing Research Institute (AMRI) and was funded by Dr. Jordan Miller’s lab for microphysiological systems and advanced materials. An overview of this project and the research in which it will be used can be found here.

This project is unique in that it appropriates existing, affordable laser hardware, namely laser cutters, for use as in the SLS process. This changed the nature of the challenge from one of procurement (ie, where to find a sufficiently powerful laser and optics) to one of integration, modular hardware design, and material development. The openSLS hardware is designed to be a drop-in powder management module whose sole purpose is to synchronously lay out layers of powder for the laser motion system (the laser cutter’s gantry and laser) to sinter or melt. By adapting commercial and widely available laser cutters for this process, the barrier to entry for this technology can be lowered.

via OpenSLS – RepRapWiki.