- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

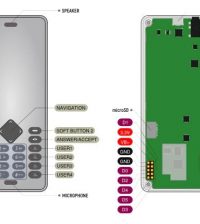

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

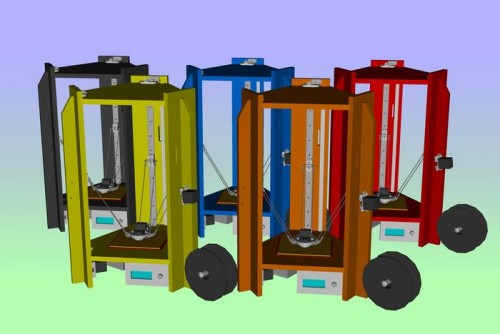

DeltaTrix 3D Printer is Open Source & Fully Hackable

Ever once in a while a good 3d printer project that is committed to be really open source and hackable comes up. The overall setup of the DeltaTrix printer is very similar to that of our amazing 3Drag (repetier, modded Marlin firmware, etc…)

Main features:

Linear delta robot layout provides a mechanically simple motion platform for moving the print head only, not the workpiece.

Off the shelf RAMPS electronics allow for easy replacement in case things go wrong.

Using a LCD display and SD memory card (supplied in our kits), the DeltaTrix 3D Printer can operate on it’s own. It does not need to be attached to a computer.

There are several (Open Source) options in terms of software. At the moment we are using Repetier on the PC, a modified version of Marlin as the firmware on the RAMPS electronics, and the standard Arduino IDE for tweaking the firmware.

A heated bed with glass print surface, allows for PLA and ABS to be used as filament.

In terms of filament, the DeltaTrix 3D Printer is designed to accept 1.75mm PLA and ABS on a variety of 1kg reels, as long as it is of good quality.

Igus linear slides with pretension are used, providing a robust and durable bearing solution from a highly reputable manufacturer. The strengthening ribs on the uprights keep the rails straight and sturdy.

The current design print head assembly uses a single Reprappro Hot End, with a nozzle size of 0.3 or 0.5mm. The assembly also has a fan and integrated duct for cooling the top of a print.

Quick changeover print head assembly. Useful for swapping between two print head assemblies, eg. one for ABS and one for PLA. The prototypes use connection blocks, but the kit will have proper connectors. Please, note: the standard kit only contains parts for one off print head assembly

via DeltaTrix 3D Printer – Open Source & Fully Hackable by Richard Tegelbeckers — Kickstarter.