- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

3D Printed Composite Keyboard Switch Prototype

Researchers Alec Peery and Dušan Sorma at Ohio University have been exploring a mechanical keyboard concept with a 3D-printed dampener built in, to avoid typing injuries.

In fact the average computer user applies two to seven times the necessary force needed to activate a keyboard’s keys, slamming them down, then experiencing a sudden stop.

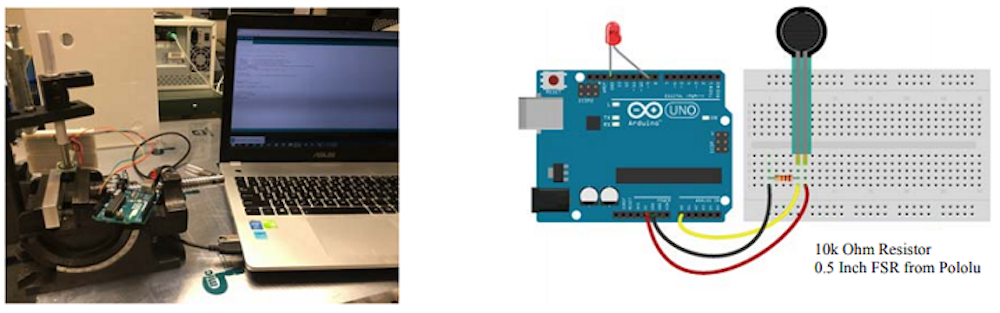

So the researchers have modified a Cherry MX keyboard switch through CAD modelling and 3D printing to incorporate damping regions in the lower half of the switch housing. The result is a composite (plastic and rubber) keyboard switch that is ergonomically superior to a traditional injection moulded plastic switch. The force damping properties of the switch housings were tested with an Arduino UNO microcontroller and force sensing resistor resting on the key tops.

“This paper is a demonstration of how 3D printing can be used to create a composite (plastic and rubber) keyboard switch that is ergonomically superior to a traditional injection moulded plastic switch. The prototype switch developed in this project aims to reduce impact forces from keyboard use exerted on user’s fingers by “cushioning” the act of bottoming out the switch during a key press. This concept is significant to industry because it aims to reduce overuse injuries caused from work on computer, a portion of the $20 Billion a year owed in worker compensation in the United States. A commercial Cherry MX keyboard switch has been modified through CAD modelling and 3D printing to incorporate damping regions in the lower half of the switch housing. The switch housings were simultaneously 3D printed with plastic and rubber and their force damping properties were tested with an Arduino UNO microcontroller and force sensing resistor resting on the key tops.”

Further information can be found in the full research paper.