- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

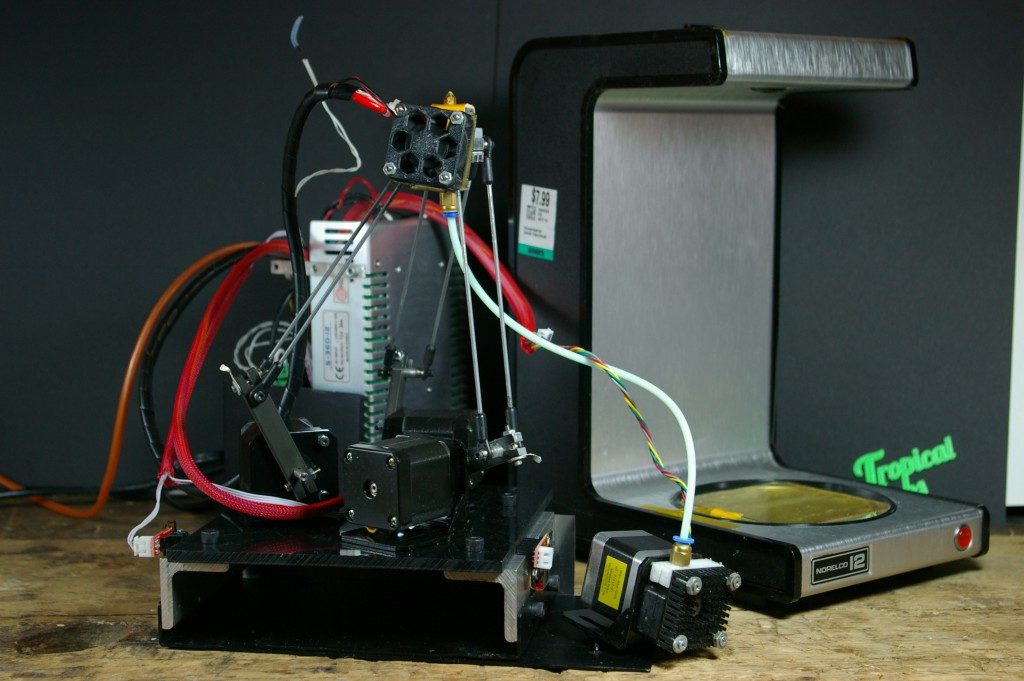

Revolutionary 3d Printing Coffee Maker, sugar free!

Have you ever thought to improve your coffee machine features? Tropical Labs not only thought about it, but they also made it real by creating something different, maybe better: a delta-style 3d printing out of a coffee maker.

They entirely circumvented the need of most 3d printers for linear rails and bearings by using a Clavel positioning system – the original delta robot design. Three stepper motors move the extruder in a delta configuration using nothing but rotational motion and simple links.

To build the printer, Tropical Labs needed only 11 components:

- Coffee maker, obviously – Tropical Labs used an old Norelco 12 model they found at a thrift shop, but any coffee maker with a hot plate should work

- Arduino Mega 2560

- RAMPS 1.4

- A4988 Stepper Motor Driver Carrier

- Nema 17 stepper motors (Tropical Labs used 0.9 degree)

- Home switches, optical or otherwise

- 3D printer hot end/extruder – again, any kind will do; Tropical Labs snagged theirs on eBay

- 12V power supply

- Solid state relay –Fotek SSR-40 or similar

- Ball joints

- 4-40 threaded rod

The company is still in the process of adding full instructions to Hackaday and to their website, but according to Tropical Labs’ Joe Church, the print bed temperature is regulated by the solid state relay that controls the power. The stepper motors control the delta mechanism, and best of all, the completed machine is multifunctional.

“The coffee maker itself did not need to be modified, so you can actually slide the delta assembly off and make a pot of coffee!” Church says

The design will remain fully open source and the same Tropical Labs encourages all the makers to steal their idea. In terms of firmware, they used a modified version of FirePick Delta version Marlin.

This is a truly creative and fun company that clearly knows its printer mechanics. As you can see below, the coffee maker 3D printer prints quite well: