- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

Open Source 3D Bioprinter to Generate Complex Vessel Tissue

Researchers from the University of Toronto have developed an open-source, low-cost 3D bioprinter for constructing complex vascular tissue structures. This research contributes to the ambitious goal of many scientists working in regenerative medicine – which is to create functional 3D printed organs.

Using sacrificial materials such as gelatin and pluronic F-127 (PF127), a thermogel polymer, the research determined PF127 as the superior material for use in developing vascularized tissues.

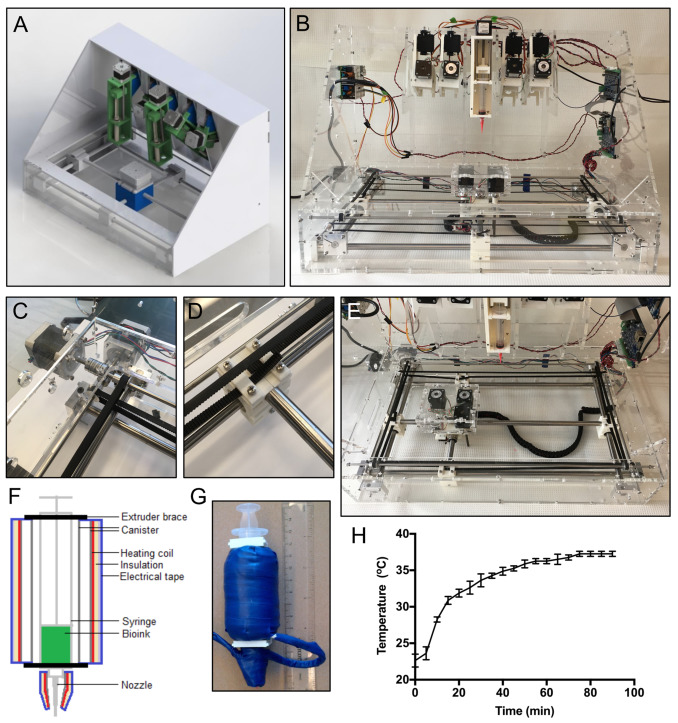

During this experiment, researchers used their custom 3D bioprinter, which cost an estimated $3,000, to print the gelatin and PF127 materials within hydrogel constructs into a desired vascular pattern.

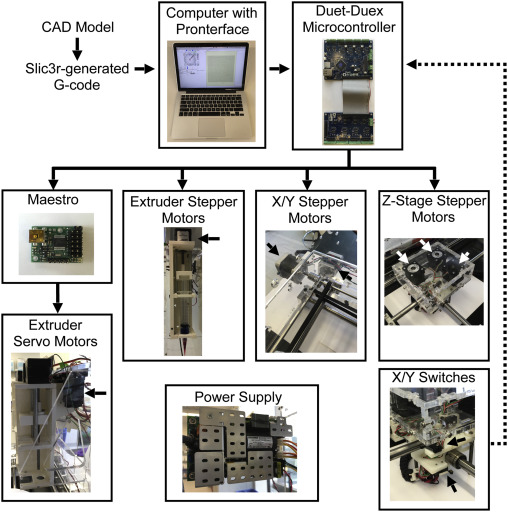

The modular 3D bioprinter included extruding systems 3D printed from ABS, to hold sterile 10 ml syringes. In addition, the printing system operated from an open-source Duet v0.6 controller board, which to managed five-axis motors (one in X, one in Y, and three in Z) and five independent extruders.

The bioprinter successfully processed the sacrificial materials, maintaining a uniform filament diameter, to replicate complex vascular tissue structures, making it particularly suitable for engineering smaller vascular channels.

For further information you can read the original post on 3dprintingindustry.com or the full research paper published by the Universtity of Toronto.