- Building a 3D Digital Clock with ArduinoPosted 4 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 5 months ago

- Snowflake with ArduinoPosted 5 months ago

- Holographic Christmas TreePosted 5 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 6 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 7 months ago

- What is IoT and which devices to usePosted 7 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 7 months ago

- Make your curtains smartPosted 7 months ago

- Configuring an ESP8266 for Battery PowerPosted 8 months ago

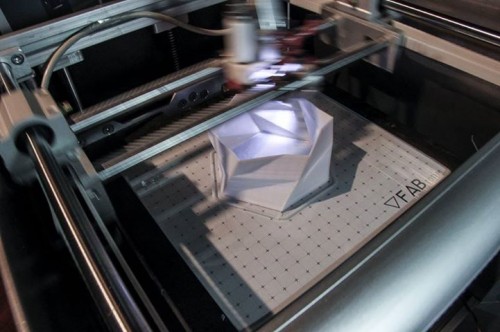

Interview to the FABTotum Team: the Personal Fabricator that wants to Change the Rules

The excitement around the new personal fabrication tool that is raising funds on Indiegogo is growing every day: the funding object has been pulverized in few days and the team is already working on adding new extended stretch goals. In this new episode of the “Meet The Funders” column, we host an interview with Marco Rizzuto, one of the funders, together with Giovanni Grieco, both coming from Milan, the Italian Hub of design and fabbing.

[Open Electronics] Where does the FabTotum idea come from?

[FABtotum] We both (founders) have a background in the field of architecture: a field in which the components you use are mainly those in commercial catalogs and customization is minimized.

Among the young designers and architects coming from the best Italian universities there is a weak familiarity with personal fabrication, which is mostly perceived as “3d printing”.

Most people, outside of the makers, geeks or personal fabrication evangelists as Neil Gershenfeld never really questioned what social impacts could the penetration of these persona fabrication practices could have.

When we started, we were mainly interested in CNC to develop architectural models: by knowing both 3D printers and CNCs we accepted the challenge to make the hybrid technology the standard for the next generation of printers.

It was in 2011 and, at that point in time, we had a vague idea of how this device should be.

The project was called “Protos” and was even more versatile than FABtotum, if you only count the hybrid capabilities: in fact it could work with more materials, a bit like mebotics Microfactory of. Protos was, however, much more expensive and could not scan. It was cumbersome from a construction standpoint and it was too slow for additive printing.

We realized that instead of bringing new people to personal fabrication we actually would have scared them to death. So we found a compromise in integrating and simplifying many things in order to reduce costs.

FABtotum is not more complex than any 3d printer. It uses fewer parts and is more precise than that from the last generation. When MakerBot Replicator 2 was presented, with a iron chassis, we already had a prototype for nearly a year that was entirely based on aluminum-magnesium aviation alloy.

At one point we had a product in hand, that we would like turn it into a stable job, but no idea on how to proceed.

For a few months we showed something around and the result was always the same: people standing with their mouths wide open for the surprise.

In April 2013 we presented the prototype in the S2P competition of the Milan polytechnic and we won. At that point we had the luck to meet great advisors, such as other startuppers or the POLIHUB staff: between a video shooting and an intense business management sessions we moved out of the garage and started acting as a small startup.

[Open Electronics] What was the role of the Polytechnic of Milan, and above that of the Polihub?

[FABtotum] The Polihub incubates young startups and through its Foundation it creates competitions such as the “switch 2 product” (s2p that we won recently), through which new ideas could win an incubation period. Beyond the allocated resources, as we are talking of an Italian public university these are few, co-working spaces are an ecosystem in their own.

When you walk through the accelerator door you meet interesting, creative, positive, competent people: for a moment you forget the once great and now miserable industrial reality of Italy.

[Open Electronics] Why this is almost the first machine trying to integrate all these technologies at this level of potential? Think the fourth axis for example.. Why no one has been so ambitious before Fabtotum?

[FABtotum] FABtotum does not consist of alien technologies: it’s made of simple solutions and a massive integration, think exactly to the fourth axis you mentioned that allows many options).

History has been made often by those re-inventing existing technologies and adapting them to a new paradigm of use. This is our real strength. We did think about the machine but about the use cases.We wanted to challenge the idea that a device can’t cover almost all of the functions required for prototyping for personal use. We started wondering about the social implications of a personal manufacturing device and about the effects on people

To be honest, one of the greatest satisfactions was seeing people of different ages and backgrounds contacting us to integrate FABtotum in their hobbies or workflow.

Doctors wanted to print prosthesis, modelers create realistic pieces. Designers wanted to test their prototypes and do reverse engineering, jewelers wanted to wax prototype with printers and electronic engineers wanted to create double layer, 4 axes circuits.

Not only Makers: the best evidence that we were on the right way.

Fabtotum doesn’t drill or cut heavy slabs of wood or steel, and therefore it cannot be really called yet a true “fabricator”, but rather a multi purpose prototype: it is the same for ABS and PLA artifacts, a fair compromise for the needs of the 21st century maker!

[Open Electronics] What have been the major challenge?

[FABtotum] The major challenges at now are those of communication rather than design.

An idea of an innovative product alone is not enough to tell people why they should rely on this technology, we must them “dream” with an overview vision.

Obviously it is also important that the technology is solid, and for this reason we iterated up to 10 times for of a single component until it reached the desired quality.

We often find ourselves in front of unexpected challenges: these stop us a couple of days and when we solve the problem we have improved the entire device.

[Open Electronics] What other stretch goals we are coming?

[FABtotum] In addition to extra colors and a heated plate (!) We decided to introduce a memory card on board (only accessible when the cover is open) to store a file.

We soon realized, however, that without a screen and an interface we could only run a single uploaded file to SD. FABtotum however does not have enough space for these devices and the costs would rise excessively.

In these cases, as in others, our motto is “a critical issue is a starting point for improvement”.

For this reason we plan to introduce a bluetooth module to compensate for the lack of connectivity and give the ability to control the print performance from your smartphone or tablet, to monitor consumption, send file or email a scanned object (in pointcloud ).

These apps would obviously be freely programmable and distributed by third parties.

The biggest challenges is also to integrate the abnormal amount of features on the software platform, but by appealing to the creativity of millions of developers we think that these issues will eventually solved thanks to open source software.

[Open Electronics] According to you, at a more general level, is there a specific room for Italy in the personal fabrication revolution?

[FABtotum] Italy is by definition a country of autonomies: of opinions, means and purposes.

Personal fabrication not only makes sense as a de-centralization of productive resources and means, it is not a kind of communism 2.0, instead it gives powerful tools to creative people who do not have access to instruments of serial manufacturing.

Integrated tools such as FABtotum can replace some needs but they can’t certainly make up for the small-scale industry.

On the other hand, the Italian makers movement is still very prolific and I think that we will see the maker philosophy permeate everywhere. My hope is that the tools for personal fabrication can bring people together rather than divide them “isolating” each with their own tools.

Personal fabrication is a tool for communication, to overcome local differences and gather knowledge from different people.

An artist who knows very well how to shape, an engineer who develops electronic anthropomorphic robots and a computer science student might now have the idea for an a high-tech toy that could be prototyped, tested and shown to investors and, why not, go on the market and create new jobs.

[Open Electronics] There is an interesting vision in your presentations and your dev blog refers to a megatrend (I share the same idea), about consumers increasingly becoming final product designer that customize products before buying them. Do you have any extensions in mind for FabTotum related to this? (I think to portals to exchange files and maybe even sell them).

[FABtotum] Now it is understood that in the Gaussian curve of the consumer market, for every billion buying an iPhone there at least a dozen people who would buy a road cone-shaped hat that lights up when you cross the street. And no, they aren’t patients of a mental clinic!

As absurd as it sounds that’s the long tail and it’s a huge chunk of the market. Someone said that the market of the 20th century was made of 10 products sold to 100 million people and that, in the 21th, it will be made of the 100 million products sold to 10 people each.

I can cope with this idea, at least partly, but I would relaunch the concept differently:

While it is true that the consumer-designer is there, I think the “sciura maria” (cit. FrankenGarage, Ed: it’s the Italian for average Joe) it’s not part of the same category and would be left behind.Personal fabrication is the more democratic technology on earth and it is up to us, developers and builders to avoid too much segmentation in this market.

The idea of a back end is interesting and has been explored. For now we have the priority to develop the platform, but provide ” on demand objects” (with rewards) is one of our future goals.

Thank you for asking .

[Open Electronics] What is your opinion about DRM technologies and digital manufacturing? What role will the future of FabTotum?

[FABtotum] Every time I hear about a new technology for “DRM in digital manufacturing” I smile.

Initially I’m compassionated but then it turns into mockery. If software was able to handle the level of abstraction required to implement the DRM controls on scans and prints, probably, looking at the window we would see T-800 exterminating mankind.

Seriously, I do not see any instance to which DRM can become an obstacle in the short term. On the other hand I do not want to underestimate the problem (as well as the problem of controlling things such as replicated weapons). Unlike software piracy I do not think there is an easy compromise: people will be free to have their replicated goods or companies will adapt by introducing non replicable complexities.

From the point of view of personal fabrication manufacturers I don’t think it is reasonable to expect containment measures about their users. Being FABtotum open we skip this problem at the very source.

As usual, our wallet will be our best way to vote on the market. Consumers make careful choices.

[Open Electronics] How the capabilities of Fabtotum scanner compare with those of the MakerBot Digitizer that promises to revolutionize Desktop Scanning?’

[FABtotum] It’s not my habit to comment on other people’s projects so I’ll leave it to the FABtotum system: it integrates various scanning methods (fixed smooth and line, but also rotating line and finally a Z digitizer with high density/accuracy). With the appropriate software these systems can be integrated. For example, you can scan an object with the laser and finally create a detailed cloud of one part with the probe, or using the laser as a prescan to set the 4d scan with the probe. Despite this variety, the system is perfectly integrated in the FABtotum platform without extra engines, sharing a large variety of systems with the other axes, with a negligible extra cost.

[Open Electronics] Looking at the website one sees how Open Source has been central in your development. Especially from a software point of view: did you borrow something specific from the community also in hardware design?

[FABtotum] Certainly!

Without the open source community we would not have the means to control the mechanics!

The scanning software is currently a script processing that is a placeholder for the final one, we use the legendary Pronterface of kliment, Marlin (although with some marginal mods). Of course at the heart of the FABtotum there’s an Arduino Mega with the classic RAMP and the hateful Allegro, even if in the final version we will probably something more versatile and integrated, still Arduino-derived.

Also we use Slic3r and the full range of open source software available. Certainly some software are also served for the creation of toolpaths used to machine the pieces of FABtotum in the prototyping stage.

[Open Electronics] The choice of a CC BY NC SA is not always ideal to give birth to an ecosystem around the product (for example due to the fact that prohibits commercial applications). However, access to schematics can be a resource for those interested in tweaking the machine for tuning. Can you tell us your point of view? Even in relation to your business model.

[FABtotum] We fully agree on the defects of the CC-BY-NC-SA. But a 3d printer is not as prolific as a framework like a physical computing platform such as Arduino, just to mention one. Certain technologies related to particular solutions have been patented, not so much to avoid the emergence of clones but essentially to protect investors that require security.

There is no nefarious intention if not that to protect your project (also from patent whoring).

Given that the FABtotum “platform” has a customizable software component with its own features and an interchangeable tooling heads, we left developers free (they may resell proprietary software if they believe) and we predict that any third party developer may create a head that can be marketed freely without our authorization or mediation.

30mW laser heads, Pick’n’Place, syringes, cutters, dual extruders … the things one can try are many and we will hopefully see a community to form around this new platform for personal fabrication.

On our end, we will continue to listen early adopters and follow their directions, working to improve the FABtotum every day.

Did you like the post? Follow @meedabyte and @openelectronics

Pingback: Interview to the FABTotum Team: the Personal Fa...

Pingback: Ten Incredible Open Source Design Projects setting New Standard | Open Electronics

Pingback: Italian FABtotum is the most successful European crowdfunding Campaign | Open Electronics

Pingback: 2013 年最不可思议的 10 个硬件开源项目 - IT讯息,最新IT咨询

Pingback: 2013年最不可思议的10个硬件开源项目 | FuckDay

Pingback: 2013年最不可思议的10个硬件开源项目 | FuckDay

Pingback: FABtotum hits Production | Open Electronics