- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

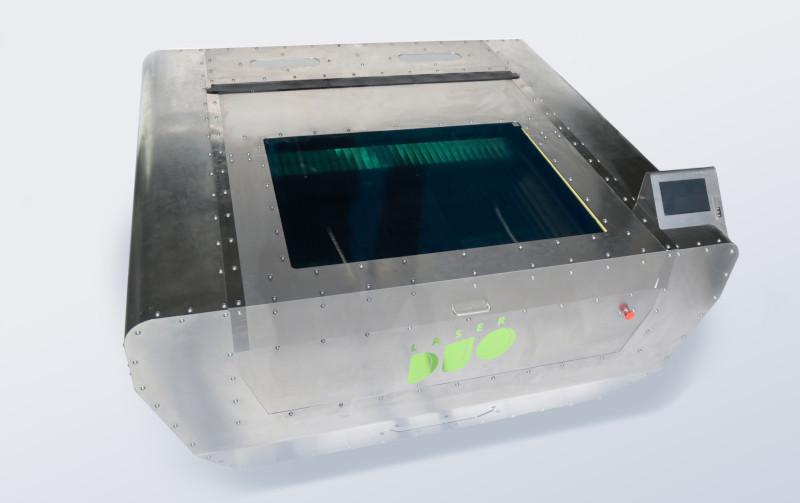

LaserDUO: the Open Source Dual Laser Cutter

LaserDUO is an open source dual-wavelength laser cutter that includes a 130 W CO2 laser and a 75 W Nd:YAG laser and which cuts at a speed of up to 800 mm/s at a resolution of 25 microns (1000 dpi). Working volume is 1500 x 1000 x 500 mm. The cutter is fully enclosed.

LaserDUO is an open source dual-wavelength laser cutter that includes a 130 W CO2 laser and a 75 W Nd:YAG laser and which cuts at a speed of up to 800 mm/s at a resolution of 25 microns (1000 dpi). Working volume is 1500 x 1000 x 500 mm. The cutter is fully enclosed.

Developed and built in a Fab Lab as multipurpose machine, LaserDuo allows to access the laser cutting technology at lower price in comparison to similar machines available on the market. Especially considering the possibility to work with metals. The open source design allows the user to fix the machine by himself, and to be aware of the process in a way that he can use it to reproduce the machine or parts for it. Being a challenging project from several aspects, such as size of the working area, Z-axis, speed, resolution and the dual laser, it also offers additional features like an integrated PC to control the machine and launch jobs, and the opportunity to have a 3D printer nozzle. The 3D printer nozzle can transform LaserDuo in a 3D printer, having 1 cubic meter of printing area.

The maker is going to open-source the entire project, starting with the custom motor controller that he uses, the Satshakit-grbl. He’s looking to release final plans for the cutter in August after he has duplicated the build at Hamburg University. The two lasers mean that it can cut a wider range of material than most: the CO2 laser can cut or engrave wood, fabric or MDF while the 75W Yag laser can burn its way through harder materials such as brass, stainless steel, copper or marble.