- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

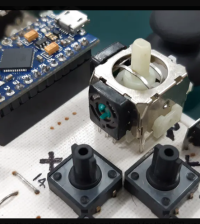

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

Autodesk and Voxel8 moving forward with 3D Printed Electronics

My impression is that this Autodesk strategic project potential just went a little underestimated:

Autodesk is developing Project Wire, a Spark Powered design tool for creating 3D printable electronic devices. We have partnered with Voxel8 to enable the fabrication of truly freeform three-dimensional circuits for the first time.

We believe future electronic devices will be printed rather than assembled. Fabricated layer-by-layer as a single object, rather than assembled from separate parts. Although 3D printing is often associated with throw-away plastic ‘trinkets’, together with Voxel8 we are looking to make functional printed devices a reality. Today we are starting with electronics by enabling the design of 3D wires embedded in printed models.

Project Wire is a new design tool under active development at Autodesk that provides electronics and 3D printing enthusiasts with the ability to place components, route 3D wires, and output multi-material print data for fabrication.

See the amazing example with the USB LED or with the, bigger, drone model.

via Autodesk and Voxel8 to make 3D Printed Electronics a reality | Spark.