- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

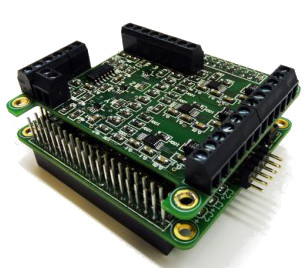

Raspberry Pi pulse generator HAT

CNC Design Limited has launched a Pulse Train Hat (PTHAT) add-on board for the Raspberry PI designed to “make motor control easy, fast and accurate.” The Raspberry Pi HAT compliant board lets customers use simple serial ASCII commands to generate clean, fast and accurate variable frequency pulses. The chief application is to drive stepper/servo motors that use pulse and direction lines, such as motors found in 3D printers, CNC machines, and robot arms.

The PTHAT Mainboard is equipped with a 100MHz Cortex-M4 MCU and direct digital synthesizer (DDS) pulse generators and can be expanded with an optional Add-On board that increases the single-channel capability to four channels. The add-on also provides additional I/O functionality.

The device can presumably work with any Raspberry Pi that supports the HAT spec.

CNC Design has also created a dedicated Pulse Train Hat support website, to ease the learning curve involved with pulse generation control.

The PTHAT Mainboard specs are as follows:

• 100MHz Cortex-M4

• Dedicated DDS pulse generators with 0.01Hz resolution for each channel

• Up to 4x individual pulse train outputs (X,Y,Z,E)

• Step, direction and enable 5V outputs for each channel

• Limit switch and emergency stop inputs

• 3x Aux switched 5V lines for switching on extruders, heated beds, etc.

• 2x ADC inputs for monitoring sensors or for speed control, etc.

• Counter for each pulse train with auto stop

• Up/down ramping to allow motors to run at higher than normal speeds

• Pulse train speeds of 0.01Hz to 125kHz output

• JTAG connector for easy updating of the firmware updates