- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

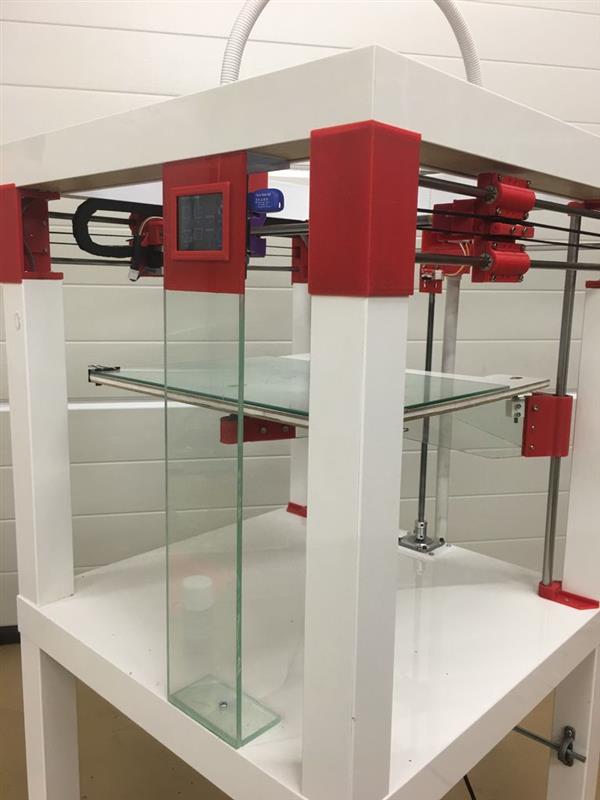

Printtable: the large-format 3D printer made from two IKEA tables, yours for under $395

A 3D printer made out of a table? While we’ve never seen much additive manufacturing potential in our furniture, nor eaten dinner off an Ultimaker 2, Wayne Mason-Drust’s unusual hack turns a symbol of 21st century chic into a machine of 21st century capabilities, making it a project well worth trying…knock on wood. Parts for the stylish DIY machine can be bought for less than $395, and the entire building process has been reduced to 25 simple steps.

The end product of Mason-Drust’s unusual idea is Printtable, a fully functional 3D printer built out of two IKEA Lack tables, an MKS TFT 28 touchscreen, a handful of stepper motors, several 3D printed parts, and various other components. Inspired by the RepRap Prusa i3 kit, Mason-Drust wanted to create an open-source 3D printer that could be built, repaired, and modified by amateur makers, but he also wanted to create something stylish and professional-looking—attributes less commonly attributed to RepRap machines.

“The most difficult part of the development of the Printtable was keeping the printer aesthetically pleasing, keeping it as clean and simple looking as possible whilst using a wide variety of different materials and ensuring they complimented each over despite their differences,” Mason-Drust told 3Ders.

The Instructables page for the Printtable project, created following a positive response from the 3D printing community, contains a complete list of parts required for the custom 3D printer. According to Mason-Drust, these can be sourced for less than $395 or £275. The designer has also uploaded the STL files for the 10x 3D printable parts of the machine. Although the project is time-consuming and relatively challenging, Mason-Drust has uploaded video demonstrations for each stage of the process, helping to make the Printtable experience accessible to all.

Printtable specs:

- Dimensions: 100 x 55 x 60 cm

- Build area: 340 x 320 x 300 cm

- E3D lite print head with Volcano hot end; Epoc 100K thermistor

- E3D Titan extruder

- Interchangable Nozzles: 0.4 (standard fit), 0.6, 0.8, 1.0 & 1.2

- 1.75mm filament

- Temperature Range: 260°C (upgradable via open source hardware)

- 2.8” TFT Touchscreen

- Run G-Code directly using integrated USB dongle or SD Card

- MKS S Base running Smoothieware

- Built-in SD & USB port (no PC connection required)

- RJ45 ethernet connection

- Can be controlled via web browser or direct to PC

- Compatible with Octoprint, Mattercontrol, and similar

Source: 3ders.org