- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

Go Prosthetic: Affordable 3d Printed Limbs for Amputees

Peter “Max” Armstrong, a mechanical engineering student at the University of Colorado Boulder, has grown into a highly promising initiative called Go Prosthetics. After years of research, prototypes, and tinkering, Armstrong believes he has developed a low-cost and customizable prosthetic that could be deployed in parts of the world where medical aids and prosthetics are hard to come by.

On a personal level, Armstrong was inspired to pursue the project by a family friend who suffered a double amputation. After learning how much lower limb prosthetics can cost (upwards of $3,000), the student decided to see if he could do something to make a difference.

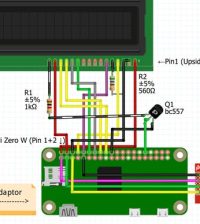

Armstrong’s Go Prosthetics technology basically consists of a “general shaped” 3D printed prosthetic socket (which come in a variety of sizes), which can be customized to the wearer by injecting expandable foam into the socket until it is a perfect fit.

According to the Go Prosthetics website, a socket fitting only takes about 30 minutes to complete and the prosthetics themselves only cost about $300 to produce—a price that Armstrong says will drop once production increases.

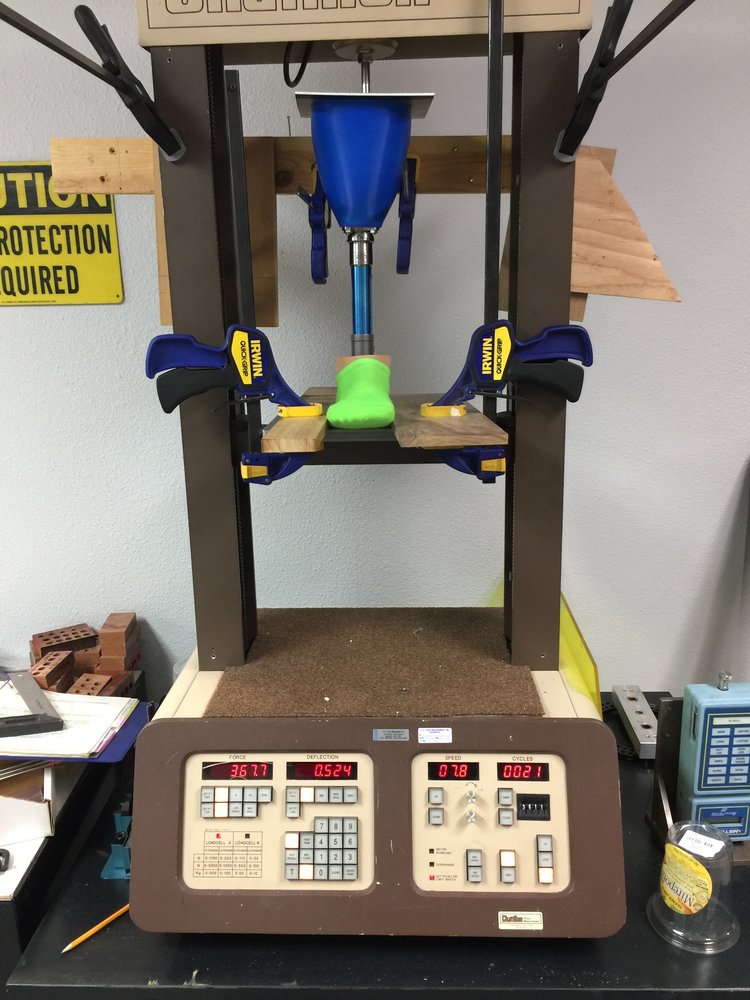

To test his 3D printed prosthetic limb system, Armstrong has worked closely with Brian Sherman, who had his left leg amputated below the knee in 2013. Sherman heard about the CU Boulder student’s work via an amputee support group in Oregon, and quickly got in contact.

Working together, Sherman has given Armstrong vital feedback on his prosthetic design, telling him if and when the socket was uncomfortable and whether it was easy to move with.

Currently, the engineering student is trying to find an NGO or nonprofit organization to collaborate with to deploy his 3D printed prosthetics. The goal of Go Prosthetics is to offer amputees in developing regions of the world better access to prosthetics, effectively giving them their mobility back. Armstrong will also keep working on his design to make it suitable for upper-limp amputees as well.

Click here to learn more about it.