- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

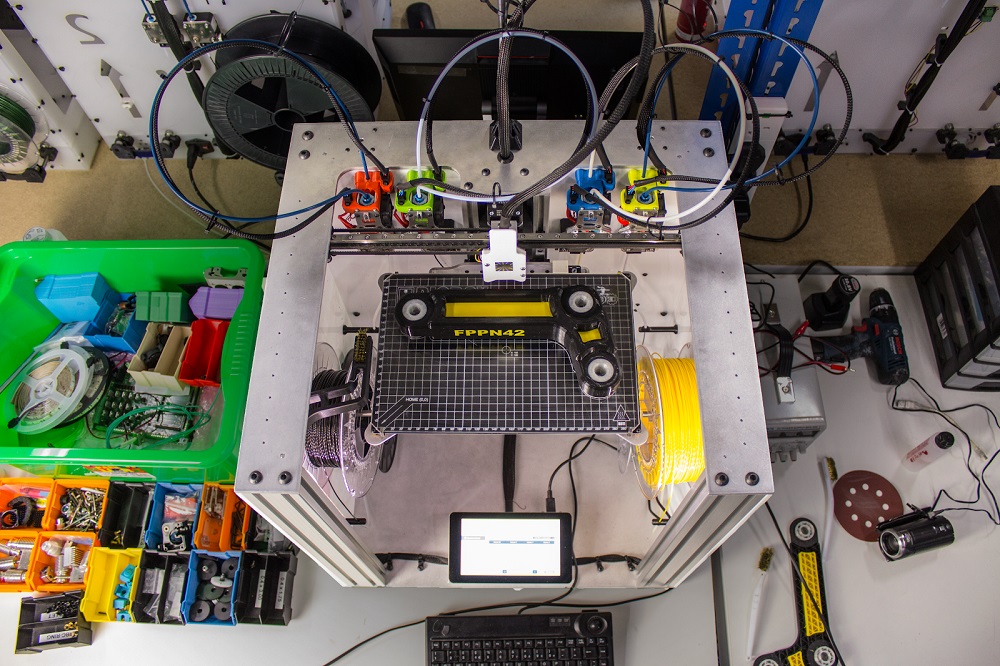

E3D Has Developed a Tool-Changer and a Motion-System for 3D-Printers

“Tool-changing is an internal passion project here at E3D, but we’re not sure whether there is demand for a machine which is just the motion system and tool-changer. Please help us figure out whether to start building and selling this thing by filling in this survey so we can figure out what you, our customers, might want from it (even if you’re not looking to purchase this particular machine right now).”

E3D has hard worked on this project, and its tool-changing adds immense value to 3d printing. The Tool-Changing allows you to use multiple materials and to print with complex geometries, different colors, and functional material combinations.

“3D printing with multiple materials is undeniably cool and useful. Not only does it allow for attractive multi-coloured prints, but also (and we believe more importantly) for complex geometries with soluble support, and functional material combinations printed in a single part. Think carbon-fiber reinforced nylon, flexible materials, and soluble support all in a single part.”

The final prototype, manufactured using DMLS technology, features an XY motion system mounted to a stiff plate of milled aluminium, along with kinematic coupling that offers high precision and reliable capture and self-aligning. A lightweight servo actuator powered grabber was a less expensive choice for toolhead grabbing, as well as “easy to actuate and control from existing electronics.”

At E3D there’s no end to the work, actually they are also developing:

- A Titan Aero extruder.

- A better extruder for flexible filaments.

- A subtractive cutting head.

- A laser, perhaps for part marking or edge finishing

- A Raspberry Pi Zero camera head, for in-process inspection

Please visit E3D’s blog post or 3Dprint.com to learn more.