- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

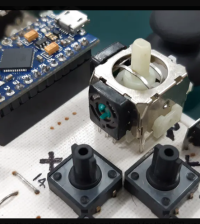

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

Autodesk’s Project Escher Applies Parallel Processing to 3D Printing

Innovators working with an effort called Project Escher at design software firm Autodesk recently told Design News they will soon release a new software product that should greatly increase the performance of 3D printing. The new solution applies a parallel processing model to 3D printing, by supporting a new type of hardware that engages multiple nozzles to produce a single item.

Corey Bloome, hardware lead for Project Escher, said in an interview that the new Autodesk product applies parallel processing, not precisely in the sense of parallel computing, but “in an analogous way, in that you have all the print heads working side by side at the same thing. It’s not computer parallel processing, it’s manufacturing parallel processing.”

In 2014, Autodesk released its own 3D printer called Ember. Ember is based on open-source technologies, including hardware, firmware, software, electronics, and materials. Escher, on the other hand, is a software-only effort. In a video from Autodesk, research scientist Andreas Bastian said that progress in the 3D printing field has been held back by “an undue focus on the actual hardware, and a lot of the software has been kind of left behind.” Escher, he said, enables “collaborative fabrication between a number of tools to describe [the] geometry in parallel, and when you parallelize fabrication, it dramatically reduces the time and cost of a lot of these challenges.”

Source: Project Escher Applies Parallel Processing to 3D Printing