- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

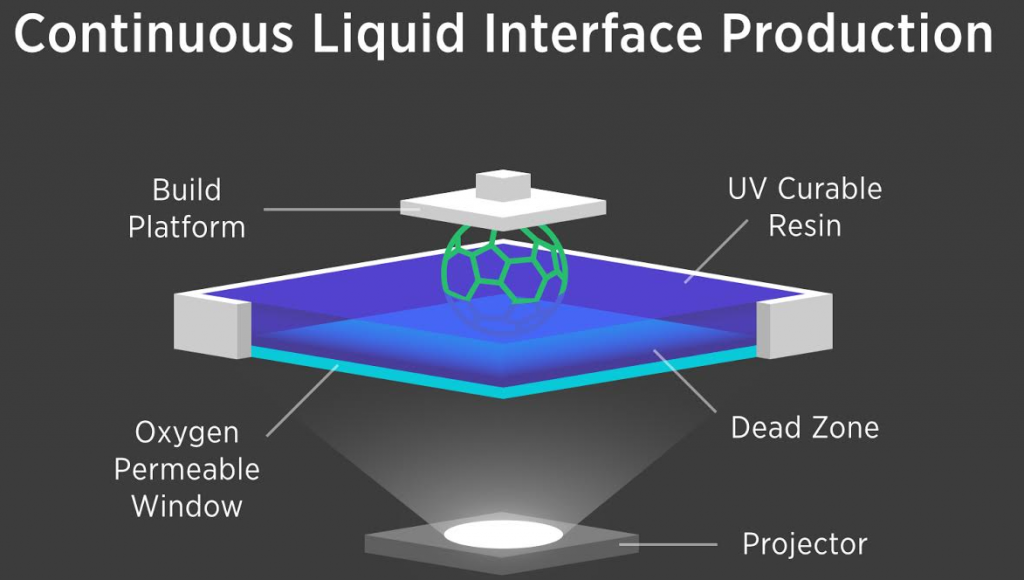

100x faster 3D printing: the future is now!

A new process for stereolithograpy has been revealed by Carbon3D, a $41M founded company by Sequoia Investment Capital.

This technology allows a 25-100x faster printing by using a special process that involves Oxygen and UV light. Thanks to this, the printing is no more done layer-by-layer but involves the full 3D volume of the resin basin.

Carbon 3D describes the process in this way:

By bringing oxygen into the equation, a traditionally mechanical technique for 3D printing suddenly becomes a tunable photochemical process which rapidly decreases production times, removes the layering effect, and provides a technology which may just take 3D printing to the next level. The CLIP process relies on a special transparent and permeable window which allows both light and oxygen to get through. Think of it as a large contact lens. The machine then is able to control the exact amount of oxygen and when that oxygen is permitted into the resin pool. The oxygen thus acts to inhibit the resin from curing in certain areas as the light cures those areas not exposed to the oxygen. Thus the oxygen is able to create a ‘dead zone’ aa4within the resin which is as small as tens of microns thick (about the diameter of 2-3 red blood cells). In this subsection of the resin, it is literally impossible for photopolymerization to take place. The machine will then produce a series of cross sectional images using UV light in a fashion similar to playing a movie.

See more details on Carbon3D on 3DPrint.com.