Sep 22, 2016 | By Andre

Josef Průša is, to me, the grandest legend in the desktop 3D printer space. When I became a little bit obsessed with 3D printing around five years ago it was the original RepRap Prusa Mendel 3D printer that I, like so many others, decided to build. It was he that continued strong with his open-source roots while other pioneers in the space closed source and changed direction.

So when I found out today that Prusa3D (a company that currently ships 1000 printers every month) announced a big firmware update for the Prusa I3 MK2 model that focuses on the current day kit builders out there I couldn’t have been happier.

Already equipped with automatic mesh bed levelling, a large 25x21x20cm build volume, onboard LCD panel, heated bed, and just about every feature one might expect from a desktop 3D printer (kit price starting at $699) this recent announcement should keep the makers out there excited.

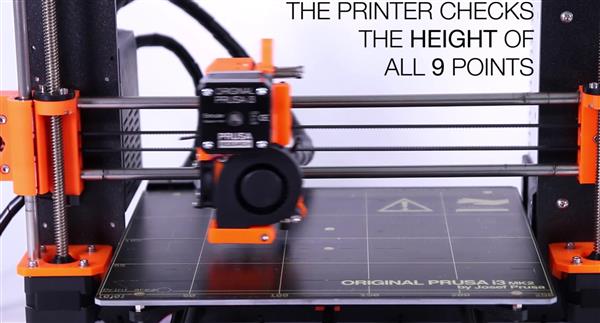

The new firmware release (available for all Original Prusa i3 MK2 models) focuses on a function called Calibrate XYZ which automatically corrects for misaligned 3D printers so to avoid a bad first layer of printing. And as anyone that’s ever worked with 3D printers would know, an unlevelled 3D print surface means warped prints at the best and damaged extruder nozzles at the worst.

The bed levelling, although not the first of its kind, is based around a 9-point sensor system that also takes into account slight imperfections of the flatness every surface has. The idea is that even though your bed might technically be level, the surface might not be. So what happens is a high resolution map of the surface height, which the printhead follows along with, is generated and this is said to generate the perfect first layer.

Of course, bed-levelling only really takes into account the z-axis. The MK2’s new features takes into account an automatic calibration of the X-Y axis as well. And while most 3D printers don’t see as much issue with these axis for the most part, misaligned x/y settings will very easily result in slanted, uneven 3D prints. The new firmware uses the aforementioned 9-point calibration system to map out the surface of the build area and subsequently calculate, and automatically correct any improperly calibrated x-y motor settings.

Prusa notes that the “XYZ calibration procedure achieves an accuracy of cca. 0.2 degrees in the skew of the machine axes, which corresponds to a deviation of 0.5mm over the print bed width. An average 3D printer builder will not achieve such perpendicularity, we often see the skew to be 4 to 8 times higher. As long as the 3D printer does not wobble, the new firmware could correct even such extreme skew and print perfectly perpendicular objects.”

Prusa3D (a company that currently ships 1000 printers every month) announced a big firmware update for the Prusa I3 MK2 model that focuses on the current day kit builders out there I couldn’t have been happier.

Prusa3D (a company that currently ships 1000 printers every month) announced a big firmware update for the Prusa I3 MK2 model that focuses on the current day kit builders out there I couldn’t have been happier.