- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

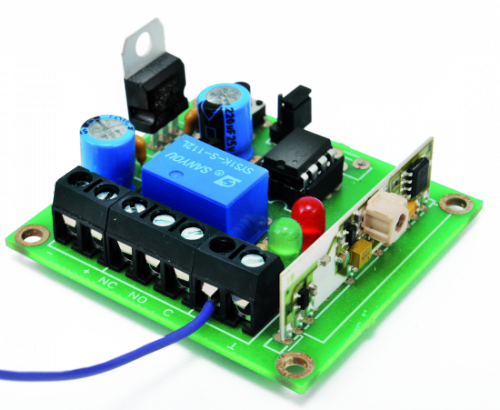

Single and Double Channel Automatic and Open Receivers

Single and double channel 433.92 MHz Receivers able to be matched to a maximum of 10 transmitter each. Monostable or bistable.

Specifications

– Number of outputs: 1-2

– Output Mode: Monostable, Bistable

– Power supply: 12 V DC

– Power consumption: 40 mA max.

– Memory: 10 codes per channel

– Encryption: MM53200/HT-12

That based on MM53200 IC is one of the oldest and proven coding adopted in general and radio gate controls: many transmitters available on the market for these applications adopt it. Being on the market for quite a long time, integrated encoders have been taken out of production and were replaced for example by UM3750 or UM86409 (both from UMC).

For this reason, it is good to have a receiver microcontroller able to adapt to this encoding, learning it in automatic mode; protecting us from chips aging and also allowing you to replicate receivers even without having the decoder.

This is one of the reasons why we have engaged in the production of single-and dual-channel receivers that you find in this post. The other reason is that by learning the code directly from a transmission you can limit the size of the receiver (you don’t need the 12-pin dip-switches instead required in manual setting) and to pair the receiver to transmitter quickly and without errors.

Both receivers described in this article are compatible, as well as with MM53200, UM3759 UM86409 encoders even with the latest Holtek HT-12, which have coding bit compatible setting.

The 1 channel diagram

Let’s start with the analysis of the single channel circuit, based on a PIC12F683 microcontroller and a hybrid module radio receiver AC-RX2, tuned to 433.92 MHz. The U2 module contains the radio part of the circuit and is a specific AC-RX2 Aurel receiver equipped with an antenna signal amplifier (which gives a sensitivity of -106 dB), super regenerating tuning stage tuned to 433.92 MHz with factory-calibrated compensator equipped with RF filter (the filter serves to improve the selectivity, which is not high in super regenerating) and amplitude demodulator. Completes the module, one digital signal squaring comparator (TTL level) coming from pin 14 and an LF amplifier output for the AM demodulator signal.

Immediately after ignition, the micro initializes its I/O, setting GP0 and GP1 as used outputs, respectively, for controlling the signaling LD2 LED (which indicates both the mode of operation, and the state of the self-learning procedure) and the NPN transistor T1 which drives the control relay of the load.

Continuing with initialization, the PIC sets GP2, GP3 and GP5 as inputs, respectively devoted to the reading of the P1 button, the J1 jumper and the output data of the AC-RX2; for the first two the active internal pull-up is active. The GP4 line is initialized as an input assigned to the A/D converter and is designed to accommodate future enhancements of the firmware. At the moment it is irrelevant to the operation of the circuit.

The circuit is completed by the power supply unit, which starts from the points + and – PWR (power supply terminal block) and reaches the three-terminal integrated regulator U1.

The firmware, after I/O initialization, flashes LD2 five times to indicate the correct start-up and normal operation, which corresponds to the execution of the distance provided command; then runs the main loop by checking both the changes in level on pin 4 (ie, the change in the state of J1 jumper) and the possible pressure of P1. A special routine periodically tests the status of the pin 2, or the arrival of data from AC-RX2; when we press one of the buttons on the transmitter, the RF signal radiated by the latter reaches the receiving antenna module AC-RX2, which demodulates the data component and sends it to pin 14 to make it available to the microcontroller, which reads from the Pin 2.

The Micro acts as a code for the code corresponding to the key pressed on the remote (but the firmware also provides a routine to automatically learn the code base without setting dip-switches) and work in this way: the microcontroller takes the TTL pulses, places them in RAM and analyzes them with an appropriate firmware routine that first of all discerns, among many signals picked up if this is compatible with the UM3750 encoding, then, if so check if the code is a those stored during self-learning, and if not deletes the data from the RAM and prepares to a new analysis.

Now let’s see what happens if the received signal contains one of the codes learned and kept by the working EEPROM: in this eventuality, appropriate handling routine of the relay starts, which determines different actions depending on whether the operation mode is monostable or bistable: mode setting is done with J1 (jumper open means monostable). If the transmission stops simultaneously but a signal from another remote control is received, matching one of the 10 learned codes, within the time-out granted by the firmware, the microcontroller considers that the transmission has never stopped.

Notice that the mode of operation of the output can also be changed during operation, ie you do not need to turn off and restart the circuit, because the status of jumper J1 is read continuously.

BOM

R1: 4,7 kohm

R2: 1 Kohm

R3: 470 ohm

R4: –

C1: 100 nF

C2: 100 µF 35 VL

C3: 100 nF

C4: 10 µF 35 VL

U1: 7805

U2: AC-RX2

U3: PIC12F683

D1: 1N4007

D2: 1N4148

LD1: LED 5 mm red

LD2: LED 5 mm green

T1: BC547

P1: Microswitch

RL1: Relè 12V

Learning procedure for Single Channel

Seen as the receiver behaves when a command arrives, let’s see how to insert the code: how learning takes place.

This can be done at any time by pressing and holding the P1 button until the green LED (LD2) lights up: then a self-learning phase began. At this point you have to transmit with the receiver to which the code is to be learnt; if the TX has more buttons and then more channels, you can learn the codes of all; So, you have to press the button of the remote control that you want to learn, and wait until the LED flashes, indicating that the learning has been successful. If the LED is flashing, it means that the memory is full or the transmitted code is not valid (it’s not the format required by since sent by transmitter with a MM53200, UM3750, UM86409 or HT-12 encoder).

Pay attention to detail: the circuit can store the transmitter codes without exceptions, except for one that provides all the bits to 1 (all the dip-switches on the radio control set to ON); then the transmitter you can use just 4,095 instead of 4,096 combinations.

To erase the EEPROM and then remove the codes already learned, you have to disconnect the power supply to the circuit and turn it back on after pressing the button P1, the latter should be issued only when the green LED remains lit fixed for 2 seconds to indicate the cancellation of memory. At this point you can release the button and the green LED will flash 5 times to indicate the exit from the procedure of cancellation and the normal start of the receiver.

| LED | Normal operation | Programming |

| LD1 | activity OUT1:on =RL1 excitedoff = RL1 at rest | – |

| LD2 | At startup or exit from learning procedure or deletion of codes, signals with 5 flashes a normal mode boot | is turned on for 2 seconds when you get into programming; flashes when the circuit has learned the code transmitted; is still if learning didn’t work |

The 1 channel firmware

'****************************************************************

'* *

'* Author : Alessandro Sottocornola *

'* *

'****************************************************************

INCLUDE "modedefs.bas"

'************************** D E F . R E G I S T R O *************************

DEFINE OSC 4

DEFINE PULSIN_MAX 1350

'OSCCON=%01110111

ADCON0 = %00000000

OPTION_REG.7=0

CMCON0 =%00000111

ANSEL=%01011000

WPU=%00000100

IOC=%00000000

INTCON=%00000000

PIE1=%00000000

T1CON.0=0

T2CON.2=0

'********************** Definizione porte del PIC *****************************

symbol SERIALE = GPIO.0

symbol LED = GPIO.0

SYMBOL RELE = GPIO.1

SYMBOL PULSANTE = GPIO.2

SYMBOL RF = GPIO.5

SYMBOL TRIMMER = GPIO.4

SYMBOL JUMPER = GPIO.3

INPUT PULSANTE

INPUT TRIMMER

INPUT JUMPER

INPUT RF

OUTPUT LED

OUTPUT RELE

'************************* D E F . V A R I A B I L I ************************

TX_MAX CON 10 'Numero di TX memorizzabili

TEMPO CON 40 'aumentarlo se in monostabile il relè va ad intermittenza

CONTA VAR WORD 'Contiene la lunghezza dell'impulso

ERRORE VAR BYTE '0:Nessun errore nel segnale - 1:Segnale non valido

I VAR BYTE 'Varibile di comodo per i conteggi e accessi all'array

TRENO VAR WORD[25] 'Contiene la lunghezza di tutti gli impulsi

COD_A VAR BYTE 'Parte alta codifica RF

COD_B VAR BYTE 'Parte bassa codifica RF

COD_1B var byte 'Parte alta codifica RF letta da memoria

COD_2B var byte 'Parte bassa codifica RF letta da memoria

TROVATO VAR BIT '1:Dato in memoria corrispondete a quello ricevuto

LOC VAR BYTE 'Locazione memoria

RICEVUTO VAR BIT '1: segnale RF ricevuto

CH VAR BYTE 'Identifica il pulsante (1,2,3,4) premuto

TEMPO_RX VAR BYTE 'Tempo trascorso dall'ultima ricezione codice RF

TEMpO_RX=0

CONTA=0

TROVATO=0

RICEVUTO=0

errore=0

'********************************* I N I Z I O *********************************

CLEAR

eeprom 0,[255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255]

low led

low rele

'RESET COMPLETO SE PULSANTE PREMUTO ALL'AVVIO

IF pulsante=0 THEN

high led

loc=0

for i=1 to TX_MAX

write loc,255

loc=loc+1

write loc,255

loc=loc+1

next i

pause 1000

low led

endif

'Inizializzo facendo lampeggiare il LED

for i=1 to 10

TOGGLE LED

PAUSE 200

NEXT I

LOW LED

'*********************************** M A I N ***********************************

'Main che gestisce sia il bistabile che monostabile

MAIN:

RICEVUTO=0

gosub CONTROLLO_PULSANTE

gosub CONTROLLO_RF

if ricevuto=1 then

high led

pause 5

GOSUB COMPRIMI_CODICE

GOSUB CERCA_SENSORE

IF TROVATO=1 THEN

if tempo_rx=0 then

if jumper=1 then

'Monostabile

high rele

else

'Bistabile

Toggle rele

endif

endif

tempo_rx=TEMPO

ENDIF

endif

if tempo_rx>0 then

tempo_rx=tempo_rx-1

endif

if tempo_rx=0 then

select case jumper

case 0 'Bistabile

case 1 'Monostabile

low rele

end select

endif

low led

GOTO MAIN

'********************* C O N T R O L L O _ P U L S A N T E *********************

'Verifica la pressione del pulsante durante il funzionamento

CONTROLLO_PULSANTE:

WHILE pulsante=0

HIGH LED

GOSUB CONTROLLO_RF

IF RICEVUTO=1 THEN

GOSUB COMPRIMI_CODICE

LOC=0

for I=1 TO TX_MAX

read LOC,COD_1B

LOC=LOC+1

read LOC,COD_2B

LOC=LOC+1

IF COD_1B=255 AND COD_2B=255 THEN

LOC=LOC-2

WRITE LOC,COD_A

LOC=LOC+1

WRITE LOC,COD_b

WHILE PULSANTE=0

TOGGLE LED

PAUSE 50

WEND

I=TX_MAX

ENDIF

NEXT I

ENDIF

WEND

LOW LED

RETURN

'*************************** C O N T R O L L O _ R F ***************************

'Decodifica il segnale RF ricevuto

CONTROLLO_RF:

' for i=1 to 5

PULSIN RF,0,CONTA

TRENO[0]=CONTA

' if conta>1100 then i=100

' next i

SELECT CASE CONTA

CASE IS >1350

RICEVUTO=0

CASE IS >1100

FOR I=1 TO 12

PULSIN RF,1,CONTA

IF CONTA<20 or CONTA>85 THEN

GOTO FINE

ENDIF

TRENO[I]=CONTA

NEXT I

GOSUB CODIFICA_MM53200

CASE ELSE

RICEVUTO=0

' SEROUT SERIALE,T9600,[13,10]

' FOR I=0 TO 12 step 1 'Visualizzo solo il dato identificativo del codice

' SEROUT SERIALE,T9600,["-",#TRENO[I]]

' NEXT I

FINE:

END SELECT

RETURN

'************************** C E R C A _ S E N S O R E **************************

CERCA_SENSORE:

'Controllo tra tutti i radiocomandi se c'è quello trasmesso

LOC=0

TRoVATO=0

CH=0

for I=1 TO TX_MAX

CH=CH+1

read LOC,COD_1B

LOC=LOC+1

read LOC,COD_2B

LOC=LOC+1

' SEROUT SERIALE,T9600,[13,10,#COD_A,"/",#COD_1B,"-",#COD_B,"/",#COD_2B]

IF COD_A=COD_1B AND COD_B=COD_2B THEN

TROVATO=1

goto FINE_CERCA

ELSE

TROVATO=0

ENDIF

NEXT I

FINE_CERCA:

RETURN

'********************* C O D I F I C A _ M M 5 3 2 0 0 ************************

'Decodifica il segnale dei sensori MM53200 e invia su seriale il codice

'identificativo <02:..........>

CODIFICA_MM53200:

ERRORE=0

FOR I=1 TO 12

' IF TRENO[I]<=28 or TRENO[I]>=80 THEN

' ERRORE=1

' ENDIF

' IF TRENO[I]>=40 AND TRENO[I]<=58 THEN

' ERRORE=1

' ENDIF

' IF TRENO[I]>28 AND TRENO[I]<40 THEN

' TRENO[I]=0

' ENDIF

' IF TRENO[I]>58 AND TRENO[I]<80 THEN

' TRENO[I]=1

' ENDIF

IF TRENO[I]<=20 or TRENO[I]>=85 THEN

ERRORE=1

ENDIF

IF TRENO[I]>=45 AND TRENO[I]<=50 THEN

ERRORE=1

ENDIF

IF TRENO[I]>20 AND TRENO[I]<45 THEN

TRENO[I]=0

ENDIF

IF TRENO[I]>50 AND TRENO[I]<85 THEN

TRENO[I]=1

ENDIF

NEXT I

IF ERRORE=0 THEN

RICEVUTO=1

ELSE

RICEVUTO=0

ENDIF

RETURN

'********************** C O M P R I M I _ C O D I C E *************************

COMPRIMI_CODICE:

COD_A=255

COD_B=255

COD_B.0=TRENO[1]

COD_B.1=TRENO[2]

COD_B.2=TRENO[3]

COD_B.3=TRENO[4]

COD_B.4=TRENO[5]

COD_B.5=TRENO[6]

COD_B.6=TRENO[7]

COD_B.7=TRENO[8]

COD_A.0=TRENO[9]

COD_A.1=TRENO[10]

COD_A.2=TRENO[11]

COD_A.3=TRENO[12]

RETURN

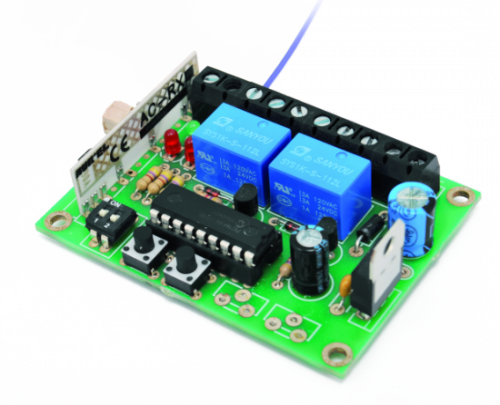

Double Channle Diagram

Let’s take a look at the circuit in 2 channels without repeating what has already been explained for the single-channel receiver; taking a look at the diagram we note the power stage for which is the argument made for the single-channel scheme. We find the stage receiver, which is also the same. The microcontroller is different, as it is a PIC16F688, whose choice was dictated by the greater number of I / O which is available with respect to the PIC12F683 used in the single-channel version.

Obviously we have two stages relay, operating as already described, and an equal protection diodes in parallel to its coils.

We also find a two-way dip-switch, which is used to set the mode of activation of the outputs of the two channels, and two trimmers, which as mentioned in the description of the single channel circuit, are currently intended for future development and are not used.

Immediately after activation (signaled by a sequence of 5 flashes of the green LED to indicate a proper boot) the micro controller initializes its I/O by setting RA4 as input to the data acquisition arrival from AC-RX2, RB4 and RB5 as inputs (equipped with integrated pull-up) to read the status of the dip-switches (such lines are activated with the internal pull-up), and the RB6, RB7 to read the state of the P1 (start learning codes to activate channel 1) and P2 buttons (start learning the codes for channel 2); also these last few lines of the I/O have active internal pull-up.

For the two relays the all is similar to the situation of the RL1 from the single channel circuit, given that the two stages are equal to that of it: T1, which pilots relay 2, is sent to saturation when RA6 is located in a high logic level, while T2 is activated by a logic high on the line RB0. Do not miss the diodes D2 and D3.

Continuing with initialization, the PIC sets GP2, GP3 and GP5 as inputs, respectively devoted to the reading of the P1 button, the jumper J1 and the output data of the AC-RX2; for the first two is the active internal pull-up.

DS1 Dip-switches are used to set the desired mode of operation for each channel; more precisely, the Dip1 allows the setting of the OUT1 and Dip2 sets the activity of OUT1. Dip closed means bistable operations, while dip open means monostable.

As in the single-channel circuit, in monostable mode the output is not timed, so it is activated by pressing the button on the transmitter and back to rest when you release the button.

Both red LEDs follow the state of the outputs during operation. LD1 lights up when the OUT1 relay is energized and LD2 lights up when the OUT2 relay is energized.

BOM

R1: 4,7 kohm

R2: 4,7 kohm

R3: 470 ohm

R4: –

R5: –

R6: 470 ohm

R7: 470 ohm

C1: 100 nF

C2: 100 µF 35 VL

C3: 100 nF

C4: 100 µF 35 VL

U1: 7805

U2: AC-RX2

U3: PIC16F88

D1: 1N4007

D2: 1N4148

D3: 1N4148

LD1: LED 3 mm red

LD2: LED 3 mm red

LD3: LED 3 mm green

T1: BC547

P1: Microswitch

P2: Microswitch

RL1: Relè 12V

RL2: Relè 12V

DS1: Disp-switch 2 vias

Procedure learning module 2 CH

To match transmitters to the circuit you must proceed as follows: press and hold the button for the channel you want to store (P1 for the OUT1 channel and P2 for the OUT2 channel). The Red LED relative to output (LD1 for OUT1 and LD2 for OUT2) turns on to indicate that it is self-learning. Once done this you have to press the button on the remote control you want to learn and wait until the LED flashes, indicating that learning is unsuccessful. If the LED is still, it means that the memory is full or the transmitted code is not valid.

To erase the memory of a channel you have to turn on the circuit by pressing and holding the button for the channel you want to delete: P1 for channel 1 (OUT1) or P2 for channel 2 (OUT2). Release the button when the green LED (LD3) remains lit for 2 seconds to indicate successful deletion of the memory bank of the chosen channel. The green LED will flash 5 times to indicate the exit from the procedure of cancellation and the start of the normal state of receiver.

| LED | Normal operation | Programming |

| LD1 | activities OUT1:on =RL1 excitedoff = RL1 to rest | – |

| LD2 | activities OUT2:on =RL2 energizedoff = RL2at rest | – |

| LD3 | At startup or exit from learning procedure or deletion of codes, signals with 5 flashes a normal mode boot | is turned on for 2 seconds when you enter programming; flashes when the circuit has learned the code transmitted; is still if learning failed |

The 2 channel firmware

'****************************************************************

'* Author : Alessandro Sottocornola *

'* *

'****************************************************************

INCLUDE "modedefs.bas"

'************************** D E F . R E G I S T R O *************************

DEFINE OSC 4

DEFINE PULSIN_MAX 1350

OSCCON=%01101110

OPTION_REG.7=0

INTCON=%00000000

ANSEL=%00000000

ADCON0=%111100000

PIE1=%00000000

PIE2=%00000000

CMCON=%00000111

T1CON.0=0

T2CON.2=0

TRISA.0=1

WDTCON=0

'********************** Definizione porte del PIC *****************************

'symbol SERIALE = GPIO.0

symbol LED = PORTB.1

symbol LED1 = PORTB.2

symbol LED2 = PORTB.3

SYMBOL RELE1 = PORTB.0

SYMBOL RELE2 = PORTA.6

SYMBOL P1 = PORTB.6

SYMBOL P2 = PORTB.7

SYMBOL RF = PORTA.5

SYMBOL DIP1 = PORTB.4

SYMBOL DIP2 = PORTB.5

INPUT P1

INPUT P2

INPUT DIP1

INPUT DIP2

INPUT RF

OUTPUT LED

OUTPUT LED1

OUTPUT LED2

OUTPUT RELE1

OUTPUT RELE2

'************************* D E F . V A R I A B I L I ************************

TX_MAX CON 10 'Numero di TX memorizzabili per ogni uscita

TEMPO CON 40 'Aumentarlo se in monostabile il relè va ad intermittenza

CONTA VAR WORD 'Contiene la lunghezza dell'impulso

ERRORE VAR BYTE '0:Nessun errore nel segnale - 1:Segnale non valido

I VAR BYTE 'Varibile di comodo per i conteggi e accessi all'array

TRENO VAR WORD[25] 'Contiene la lunghezza di tutti gli impulsi

COD_A VAR BYTE 'Parte alta codifica RF

COD_B VAR BYTE 'Parte bassa codifica RF

COD_1B var byte 'Parte alta codifica RF letta da memoria

COD_2B var byte 'Parte bassa codifica RF letta da memoria

TROVATO VAR BIT '1:Dato in memoria corrispondete a quello ricevuto

LOC VAR BYTE 'Locazione memoria

RICEVUTO VAR BIT '1: segnale RF ricevuto

CH VAR BYTE 'Identifica il pulsante (1,2,3,4) premuto

TEMPO_RX1 VAR BYTE 'Tempo trascorso dall'ultima ricezione codice RF

TEMPO_RX2 VAR BYTE 'Tempo trascorso dall'ultima ricezione codice RF

TEMpO_RX1=0

TEMpO_RX2=0

CONTA=0

TROVATO=0

RICEVUTO=0

errore=0

'********************************* I N I Z I O *********************************

CLEAR

eeprom 0,[255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255]

eeprom 20,[255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255]

low led

low led1

low led2

low rele1

low rele2

'RESET COMPLETO SE PULSANTE PREMUTO ALL'AVVIO

IF P1=0 THEN

high led1

loc=0

for i=1 to tx_max

write loc,255

loc=loc+1

write loc,255

loc=loc+1

next i

pause 1000

low led1

endif

IF P2=0 THEN

high led2

loc=tx_max*2

for i=1 to tx_max

write loc,255

loc=loc+1

write loc,255

loc=loc+1

next i

pause 1000

low led2

endif

'Inizializzo facendo lampeggiare il LED

for i=1 to 10

TOGGLE LED

PAUSE 200

NEXT I

LOW LED

'*********************************** M A I N ***********************************

'Main che gestisce sia il bistabile che monostabile

MAIN:

RICEVUTO=0

gosub CONTROLLO_PULSANTE1

gosub CONTROLLO_PULSANTE2

gosub CONTROLLO_RF

if ricevuto=1 then

high led

pause 5

GOSUB COMPRIMI_CODICE

GOSUB CERCA_SENSORE

IF TROVATO=1 THEN

select case ch

case 1

if tempo_rx1=0 then

if DIP1=1 then

'Monostabile

high rele1

else

'Bistabile

Toggle rele1

endif

endif

tempo_rx1=TEMPO

case 2

if tempo_rx2=0 then

if DIP2=1 then

'Monostabile

high rele2

else

'Bistabile

Toggle rele2

endif

endif

tempo_rx2=TEMPO

end select

ENDIF

endif

if tempo_rx1>0 then

tempo_rx1=tempo_rx1-1

endif

if tempo_rx1=0 then

select case DIP1

case 0 'Bistabile

case 1 'Monostabile

low rele1

end select

endif

if tempo_rx2>0 then

tempo_rx2=tempo_rx2-1

endif

if tempo_rx2=0 then

select case DIP2

case 0 'Bistabile

case 1 'Monostabile

low rele2

end select

endif

led1=rele1

led2=rele2

low led

GOTO MAIN

'******************** C O N T R O L L O _ P U L S A N T E 1 ********************

'Verifica la pressione del pulsante durante il funzionamento

CONTROLLO_PULSANTE1:

WHILE P1=0

HIGH LED1

GOSUB CONTROLLO_RF

IF RICEVUTO=1 THEN

GOSUB COMPRIMI_CODICE

LOC=0

for I=1 TO TX_MAX

read LOC,COD_1B

LOC=LOC+1

read LOC,COD_2B

LOC=LOC+1

IF COD_1B=255 AND COD_2B=255 THEN

LOC=LOC-2

WRITE LOC,COD_A

LOC=LOC+1

WRITE LOC,COD_b

WHILE p1=0

TOGGLE LED1

PAUSE 50

WEND

I=TX_MAX

ENDIF

NEXT I

ENDIF

WEND

' LOW LED1

RETURN

'******************** C O N T R O L L O _ P U L S A N T E 2 ********************

'Verifica la pressione del pulsante durante il funzionamento

CONTROLLO_PULSANTE2:

WHILE P2=0

HIGH LED2

GOSUB CONTROLLO_RF

IF RICEVUTO=1 THEN

GOSUB COMPRIMI_CODICE

LOC=TX_MAX*2

for I=1 TO TX_MAX

read LOC,COD_1B

LOC=LOC+1

read LOC,COD_2B

LOC=LOC+1

IF COD_1B=255 AND COD_2B=255 THEN

LOC=LOC-2

WRITE LOC,COD_A

LOC=LOC+1

WRITE LOC,COD_b

WHILE p2=0

TOGGLE LED2

PAUSE 50

WEND

I=TX_MAX

ENDIF

NEXT I

ENDIF

WEND

' LOW LED2

RETURN

'*************************** C O N T R O L L O _ R F ***************************

'Decodifica il segnale RF ricevuto

CONTROLLO_RF:

PULSIN RF,0,CONTA

TRENO[0]=CONTA

SELECT CASE CONTA

CASE IS >1350

RICEVUTO=0

CASE IS >1100

FOR I=1 TO 12

PULSIN RF,1,CONTA

IF CONTA<20 or CONTA>85 THEN

GOTO FINE

ENDIF

TRENO[I]=CONTA

NEXT I

GOSUB CODIFICA_MM53200

CASE ELSE

RICEVUTO=0

' SEROUT SERIALE,T9600,[13,10]

' FOR I=0 TO 12 step 1 'Visualizzo solo il dato identificativo del codice

' SEROUT SERIALE,T9600,["-",#TRENO[I]]

' NEXT I

FINE:

END SELECT

RETURN

'************************** C E R C A _ S E N S O R E **************************

'Zone via filo: da locazione 1 a locazione 4

'Zone Wireless: da locazione 48 a locazione 276 (3 locazioni ogni zona) > 4 sensori per zona

'Zone Panico: da locazione 300 a locazione 319 (2 locazioni ogni zona) > 10 panico

'Zone Radiocomando: da locazione 320 a locazione 399 (2 locazioni ogni zona) > 40 radiocomandi

CERCA_SENSORE:

'Controllo tra tutti i radiocomandi se c'è quello trasmesso

LOC=0

TRoVATO=0

CH=0

for I=1 TO TX_MAX*2

CH=CH+1

read LOC,COD_1B

LOC=LOC+1

read LOC,COD_2B

LOC=LOC+1

' SEROUT SERIALE,T9600,[13,10,#COD_A,"/",#COD_1B,"-",#COD_B,"/",#COD_2B]

IF COD_A=COD_1B AND COD_B=COD_2B THEN

TROVATO=1

if ch<=TX_MAX then

ch=1

else

ch=2

endif

goto FINE_CERCA

ELSE

TROVATO=0

ENDIF

NEXT I

FINE_CERCA:

RETURN

'********************* C O D I F I C A _ M M 5 3 2 0 0 ************************

'Decodifica il segnale dei sensori MM53200 e invia su seriale il codice

'identificativo <02:..........>

CODIFICA_MM53200:

ERRORE=0

FOR I=1 TO 12

' IF TRENO[I]<=28 or TRENO[I]>=80 THEN

' ERRORE=1

' ENDIF

' IF TRENO[I]>=40 AND TRENO[I]<=58 THEN

' ERRORE=1

' ENDIF

' IF TRENO[I]>28 AND TRENO[I]<40 THEN

' TRENO[I]=0

' ENDIF

' IF TRENO[I]>58 AND TRENO[I]<80 THEN

' TRENO[I]=1

' ENDIF

IF TRENO[I]<=20 or TRENO[I]>=85 THEN

ERRORE=1

ENDIF

IF TRENO[I]>=45 AND TRENO[I]<=50 THEN

ERRORE=1

ENDIF

IF TRENO[I]>20 AND TRENO[I]<45 THEN

TRENO[I]=0

ENDIF

IF TRENO[I]>50 AND TRENO[I]<85 THEN

TRENO[I]=1

ENDIF

NEXT I

IF ERRORE=0 THEN

RICEVUTO=1

ELSE

RICEVUTO=0

ENDIF

RETURN

'********************** C O M P R I M I _ C O D I C E *************************

COMPRIMI_CODICE:

COD_A=255

COD_B=255

COD_B.0=TRENO[1]

COD_B.1=TRENO[2]

COD_B.2=TRENO[3]

COD_B.3=TRENO[4]

COD_B.4=TRENO[5]

COD_B.5=TRENO[6]

COD_B.6=TRENO[7]

COD_B.7=TRENO[8]

COD_A.0=TRENO[9]

COD_A.1=TRENO[10]

COD_A.2=TRENO[11]

COD_A.3=TRENO[12]

RETURN

2 Comments