- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

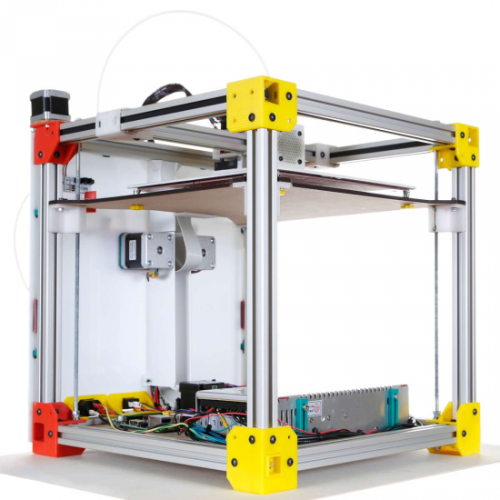

Interview to Fa)(a 3d, the first Open Source 3d Printer using a magnetic levitation system

We recently spotted a very interesting project, the 3dprinter called Fa)(a 3d: a modular, open source printer that was born out the collaboration of several Italian fablabs. The team behind the printer promotes its kit mostly thanks to a workshop that bets on the importance of a collaborative moment to build things together. We interviewed Giacomo Falaschi, is the co-founder of FabLab Contea, blogger on 3dita.falaschi.com and specialist in developing extruders (such as the double extruder with solo hot end FUM). He is the one who took the original Mondrian project, by Gillioz and reshaped it and created the final version of Fa)(a 3d.

[Simone Cicero]: What do you mean exactly with modular and scalable? Can you give us a more clear understanding of the whys behind this choice?

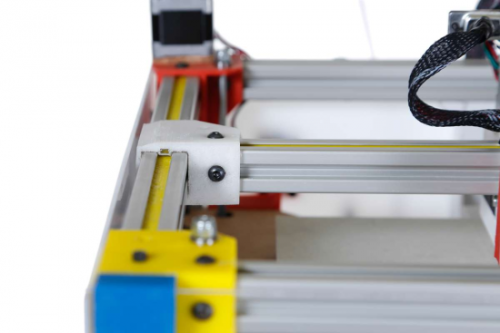

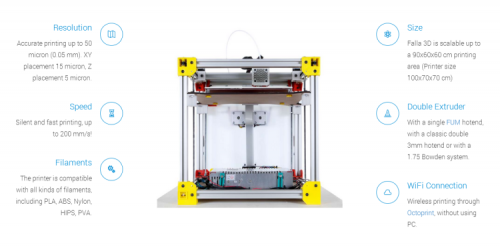

[Giacomo Falaschi]: I always found quite impossible to think not to be able to print anything and in any size so that while designing I thought about being as flexible as possible: that’s when the modular being of the printer born. In less than 3 minutes you can change the extruder and switch from a 1.75 mm filament to a 3 mm one, or switch from a bowden system to a direct one, etc…

Moreover we are working on new extruders, such as the screw extruder, the syringe extruder and a paste extruder.

The characteristics of the previous version have been improved: the Mondrian model by Emannuel Gillioz has the same scalable features so that it is possible to scale it on the height axes simply using longer profiles, while for the X/Y axes you only have a few add ons modifying the shifting on the axes themselves.

[SC]: Are you guys considering crowdfunding? I’m wondering if the printer has already been engineered (as I see your price point is quite cool). I’m really interested to know how you guys faced the problem of keeping cost as low as possible: how did you optimized the BOM? Is the KIT BOM Made in China?

[GF]: No crowdfunding (at least at the moment). Actually in every activated workshop the FabLab/MakerSpace/HackerSpace itself can create a little local crowdfunding, so that the final price of the printer is proportional to the number of the participants. The price is so low because it spoils our experience in the RepRap world: we saved money where we couldn’t find performance or quality advantages in order to spend a bit more for materials able to solve some frequent printing problems.

Regarding the BOM and using components Made in China: the answer is no, absolutely, in the Bom list we give to the FabLab/MS/HS we suggest many international sellers and only a few within them are from China. Lately, thank to the Fa)(a 3d project we have been contacted by some commercial activities willing to sell the kit to the customers who are unable to follow the workshops activated all along Italy. Of course, it has been a pleasure and thanks to them we can now develop an Italian or European solution that let you choose a printer built with almost only Italian components (even the electronics).

[SC]: This printer looks like borrowing a lot both to several open source artifacts and project and from the Open Hardware culture itself. I’m also interested in knowing more about your choice to go fully open source and why you choose GPL license instead of a more typical CC-BY-SA license. Is there any specific issue you considered? Can you just tell us more about how you guys are linked with the OSHW community?

[GF]: First of all, the Mondrian version (from which Fa)(a derives) had been released in GPL. Anyway people choose project with a GPL licence for faith and will to change the system, to avoid the disappearance of the project in a few year and to see it being modified and upgraded in a little time. Both personally and as a FabLab, we have many projects work in progress for the OSHW community…you will soon get surprised!

[SC]: Why this is just the first magnetic levitation OS printer? Is it a mature technology in Open Source?

[GF]: Yes…if Google and the community don’t lie. It is the first 3d printer using a magnetic levitation system. More than an “advanced technology” I’d define it as a mechanical expedient that unloads the burden on the X/Y axes, preventing some frequent problems of the classical bearing guides.

[SC]: How do you plan to nurture an ecosystem of mods, derivatives, etc..? Do you plan also community management activities?

[GF]: We will build a section on our website where you will be able to register your printer and have a serial number. In this way the printer will appear on a map, where you’ll be able to see the Fa)(a in the neighbourhood: this is for solve problems together or exchanging extruders etc…Everything will be in order to build up a real community, virtual and real.

[SC]: I’ld definitely know more about your wonderful idea of selling kits+workshop: are you only adopting this approach to the market? will you target a direct sale once a full instructable will be available?

[GF]: Tha basic idea is to create small collaborations independently managed by the ones (FabLab/MS/HS) joining the Fa)(a 3d project. Once the Instructables/Wiki is online, thanks to some commercial activities already collaborating with us, it will also be available a kit without workshop for people who are unable to join local Labs.

[SC]: Tell us abit more about the story of a collaboration between fablabs that is behind this printer.

[GF]: The printer is born within FabLab Contea after a 5 month lasting work with more than 70 versions of the original project. Lorenzo Hervatin is the creator of the photographic set of our FabLab, he shot the photos and the promo video with the “moving” creature. Guido Lippi follows all the social networks you MUST follow us on: Facebook, Twitter, Google +. Teresa Nannucci is our translator…she speaks quite a few languages and translated everything, starting with the website and this interview. Within FabLabContea Niccolò Casamenti also collaborated, redacting the minibusiness plan for activating the workshop.

In March 2014 the collaboration between FabLab Contea, FabLab Roma Makers and FabLab Cascina started. Thanks to Silvio Tassinari of FabLab Roma Makers we designed the graphic (logo, posters, etc) and we built up the basics for the organisation of the Bom list: everything is OpenSource in order to let other FabLabs organise the workshop in a simple and intuitive way. With Mauro Manco we fulfilled our distribution for the octopi system, to improve the integration between octoprint and our requirements; furthermore we now have a network specially created by the printer, to which you can easily connect from your pc, tablet, smartphone, etc…

Fiore Basile at FabLab Cascina manages all the events people can join, to attend workshops or presentations of our project in Italy and (hopefully) worldwide. He also is our official webmaster: he’s the one who made our website.

Having fulfilled great bonding between the Labs we are going on developing this and other projects…as soon as they are ready we will be announcing them.

[SC]: Can you also give us your point of view about how the fabbing culture is growing in italy (as you guys are for sure protagonists).

[GF]: The Italian panorama seems too often being relegated to the 3d printing area, like following a temporary trend. Of course, this is a great start, but it would be desirable to widen this ideas to other fields: making is not only printing, on the contrary it should push the developing of projects able to enclose more disciplines. 3d printers are only a part of a various and mixed world such as the maker world.

In Italy, we are really bond to an artisanal tradition linked to studios and ateliers where an expert master artisan teaches his own knowledge to the curious and willing ones going in the atelier itself. This conception really obstacles the fulfilling of a real sharing able to enlarge its public and to go beyond the walls of the atelier to reach all the potentially interested people.

[SC]: What are the next opportunities to see Fa)(a in action?

[GF]: That’s quite hard to say. We have applied for many events (Fab 10, Open Hardware Summit, etc…) and we’re still waiting for an answer. Anyway you can follow our workshops already scheduled in Florence, Rome, Caserta, Contea and Cascina. You can find any new opportunity to see Falla in action on our website.

If you need to build a Fa)(a 3d you can also ask to the nearest FabLab to help you or to organise a workshop with other people. Finally, in Italian “Falla” means “Do it”…so if you want it, than do it.

Pingback: Updates from the 3Drag 3dprinting contest: Fa)(a from Giacomo Falaschi | Open Electronics