- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

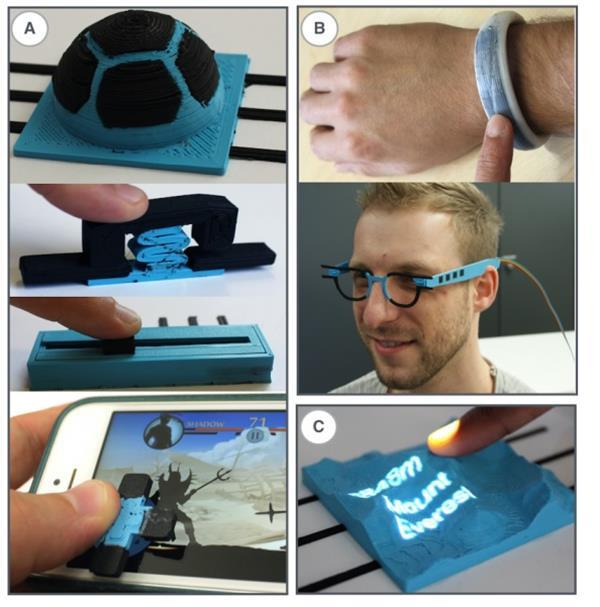

3D printing Top Trends 2016: software, sensors, and carbon nanotubes

3D printing software and formats, Carbon nanotube products, and IoT devices embedded with sensing materials are the main development trends we’ll see in 2016, according to Lux Research.

The first ‘under-the-radar’ advanced materials trend of 2016 is the scale production of carbon nanotube (CNT) products. “After years of hype and concomitant oversupply, the industry began a shakeout of undifferentiated players in 2013,” said Anthony Schiavo of Lux Research. Carbon nanotubes are cylindrical carbon molecules with excellent thermal conductivity and mechanical and electrical properties, making them extremely valuable in nanotechnogloy, semi-conductors, electronics, optics, and other fields of materials science.

The second undercover advanced materials trend of 2016 is that both 3D printing startups and majors will have to shift their focus beyond just making new 3D printers, towards creating novel 3D printing solutions, including improved 3D printing software, 3D printing file formats like 3MF, or features such as the ability embedded sensors, in order to differentiate themselves from the competition.

The third advanced materials trend of 2016 predicted by Lux Research is that the emerging Internet of Things (IoT) market has and will continue to create new opportunities for sensing materials. “The coming flood of sensors in the workplace will greatly ease communication between sensing materials and connected devices, and thus the industrial Internet as a whole. Clients should expect these lower barriers created by the rise of IoT in 2016 to speed the development and eventual implementation of sensing materials as a class,” wrote Schiavo. “This will lead to an increasing number of start-ups offering sensing coatings and materials that emerge in 2016.