- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

How to evaluate a Stereo Lithographic 3D Printers

Introduction

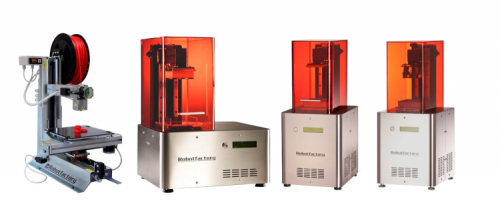

In this short document by RobotFactory, we will try, within the limits of our knowledge and of course more objectively possible, to identify what are the parameters distinguishing the various stereo lithographic 3D printers on the market at this date. The parameters that allow people to be able to make a serious comparison and make an informed assessment for the possible purchase of a 3D printer.

A comparison between the different stereo-lithographic 3D printers currently on the market, it is not easy, but through this document we want firstly to identify on an informed basis what are the characteristics that at the end, also and above all, affect in the purchase price.

Our aim therefore is to do a little bit of clarity in what now seems to be a jungle, in which is easily to get lost.

SLA – Stereo lithographic printers

The operation of a stereolithographic printer is very simple, a light source affects with a certain intensity (energy) a chemical substance (resin) in which there are one or more photoinitiators, the photoinitiators start the polymerization, solidifying so the area affected by the light source.

Resins

There are several types of photosensitive resins, which differ between them as well as for the various chemical components contained in them, even for quantities and types of photoinitiators in themselves content.

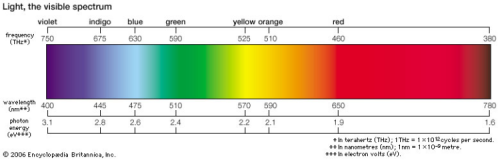

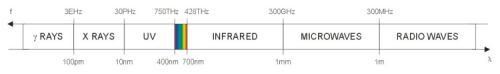

Normally the photoinitiators used for the resins in the stereo lithography are identified for the wavelength at which they react. The types used are respectively two and react to structured light, that is visible (approximately from 400 nm to 450 nm) or UV light (near UV: from 300 nm to 400 nm).

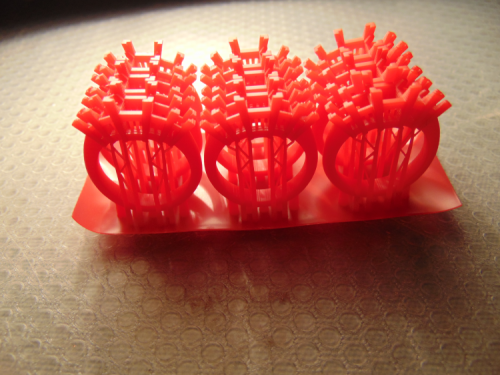

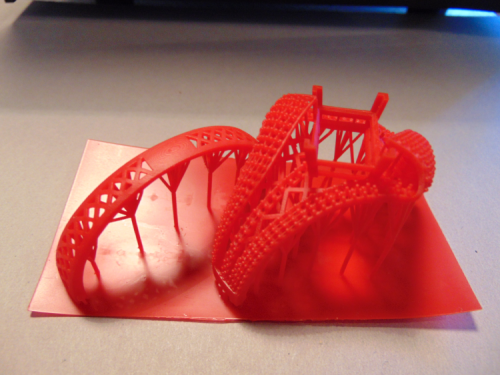

The resin which reacts to the top of the spectrum of visible light (structured) has the limitation of not being transparent, since it must contain a pigment (usually yellow or red) which prevent, during printing, the light source continues to catalyze the layers already made, accordingly deforming the object. This is a phenomenon that can have especially in very thin thicknesses, typical of the stereo lithographic printers, and the use of the pigment in the resin composition just prevents the occurrence of this issue.

Naturally the resin must respond perfectly to the uses for which it was developed, such as:

- Castable (used in investment casting)

- Heat resistance (usable for small molds by casting, and for the injection molding of the waxes in jewelry)

- Flexibility (used in specific cases)

- Biocompatibility (used primarily in medical applications)

- Hardness (used for functional or aesthetic models)

Finally, a real assessment cannot skip, the cost (per kilo) of each resin and, for this reason, the types of resins used with a stereo lithographic printer and their costs can often be a discriminating factor for the purchase thereof.

Light source

The light source used in stereo lithography can be normally of two types:

- High-pressure lamps or LED UV

- Laser Diodes.

Lamp / LED

The light is used in combination with a special component, identified with the initials DLP (Digital Light Processor), manufactured by Texas Instruments Inc. to produce the image to be projected on the resin and able to solidify it.

In this category we include the normal ‘Home Theater’ projectors, or those specifically designed for industrial 3D printers. The ‘Home Theater’ projectors of course are cheaper than the industrials, especially for the cost of lamp replacement.

The printers that use this type of light source, are faster respect of those that use the laser, as in the first (DLP) at each projection it is solidified a whole layer of resin, while in the second (Laser) the projection it takes place point by point, for each printing layer. The difference of printing time becomes more evident, building several objects simultaneously.

The projectors that use high-pressure lamps, for effect of the energy that they can produce, allow to have printing areas broader than those possible with projectors that use UV LEDs, which, currently, do not reach very high light intensities.

This type (Lamps / LEDs) in turn is diversified to the projection type, direct or indirect, that is, if the projection is reflected by a special mirror, or on the contrary it directly reaches the resin. The direct projection has the advantage of not requiring periodical cleaning of the mirror, that many times is a delicate and risky operation, because there is the risk of scratching the mirror itself, with the consequence to replace it.

In addition to the above, another fact that differentiates these types of printers is that the projector can be inside or outside of the printer, in the latter case the printer is more economic, since it is left to the customer the burden to buy the projector. Furthermore, for the structure that usually they have, this type of printers is addressed, for the achievable precision, to a public, above all, of consumers and hobbyists.

Laser

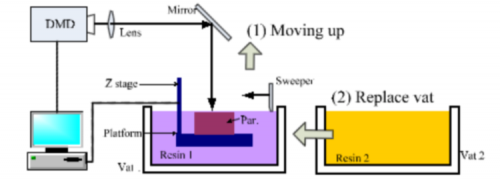

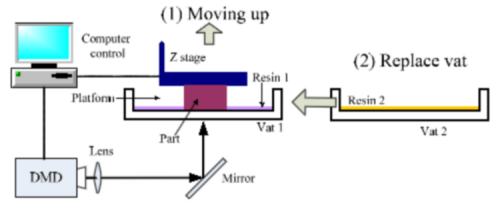

The laser is normally deflected by galvanometers, or positioned via cartesian coordinates (X – Y) to form, point by point, the figure that will solidify the resin.

This type of printers can achieve very high resolutions (which depend, anyway, by the minimum size of the spot ray), but most of the times it is slow. Furthermore, it requires specific assistance by specialized personnel, both for the cleaning of the mirrors (both those of the two galvanometers, that the one of reflection), that for the calibration of galvanometers.

In addition, in the printers using galvanometers, if the size of area to be built is very large, an issue is introduced, due to ovality of the spot of the laser beam in the extreme parts, this ‘aberration’ is to be corrected by the manufacturers through software artifices.

The better characteristics of this type of printers are these:

- it’s possible use the transparent resin

- it’s possible reach very large sizes.

Usually, for the two types described above, are used different resins, often not compatible each other.

Categories

Surely, the first difference to point out is between:

- Projection from the top – that is, the light source is located upon the resin vat.

- Projection from the bottom – that is, the light source is located below the resin vat.

- Projection from the top

In the projection from top, the object is constructed inside a container which contains the resin, so in this case, the object is immersed in the resin as it is constructed.

The major drawback of this category is that it is necessary a high amount of resin and, once used, it has a very limited duration. In fact, for the intrinsic reaction of the resin itself, once it started the catalyzation, even if no longer present the light source that triggered it, its hardening effect continues, with the consequence of greatly reduce the life of the resin (so if you do not use within a limited period the resin are be wasted).

In this category must be distinguished, in turn, two sub categories:

- Open-air – that is, the light source builds the image directly on the open surface of the resin, normally these printers are less expensive.

- Closed – that is, between the light source and the surface of the resin, there is a special film that maintains leveled the surface itself.

- Open-air

Normally this subcategory is less precise, because for the physical effect that is on the surface of the resin, said meniscus effect, the layer in solidification it is not perfectly planar, in addition it also occurs an issue due to the fact that it is difficult correctly focus the image, in an area which changes position continuously during the realization of the object.

The first problem (the meniscus effect) can be partly overcome by using a size of the container for the resin much wider than necessary, but this obviously entails an additional cost for the resin required to fill the container.

The second problem (difficulty focusing) is solved in part with leveling systems, but these generally are very expensive.

- Closed

To avoid the meniscus effect problem, it normally uses a thermoplastic fluoropolymer film under tension above the resin surface and in contact with the resin itself, this arrangement also partly solves the problem of focusing, since the resin is also pressurized.

Under this category are included professional printers, rather expensive. In recent times, in fact, it begins to see in the market the first ‘consumer’ 3D printers on which it’s trying to use this method, we will see later with what results, and above all at what cost.

- Projection from the bottom

In this category we can find the broadest range in the market today, because in it are included printers, as well as ‘prosumer’ (professional-consumer), even those properly Professional.

The first thing to note is that even in this category there are problems, both physical, that constructive, however, solved by using different strategies.

The problems that exist in the projection from the bottom are linked to:

- The vat that contains the resin

- The structure of the Z axis.

- Vat

The main problem has on the vat containing the resin.

Specifically we refer to the physical effect known as ‘suction’ effect, which is generated between the construction base and the bottom of vat. To this effect, which is created in general when a body is immersed in a liquid with a certain density and within the liquid itself comes in contact with another surface (effect that is exploited in the hooks for hanging things), there are considerable difficulties in detachment of the two elements (bottom of vat and construction base), detachment necessary to renew the resin and to build the next layer.

The solutions adopted by the various manufacturers are:

- Tilt (patented by a well-known manufacturer)

- Horizontal translation

- Rotation

- Contemporary Tilt – Shift (developed by us)

The choice of one rather than the other solution, it is strongly influenced by the presence of the patent with regard to the first solution (for inclination), from excessive noise of horizontal translation systems (which also have to be combined with a system of scraping the bottom of vat), in that the solution with rotation, having been adopted for now by a single manufacturer, is not sufficiently tested.

In my opinion, as result of objective assessments and analysis, contemporary Tilt – Shift of vat is currently the most effective solution, although more complicated to be engineered.

Another problem of the vat is the bottom of the vat itself.

The bottom of the vat must be transparent, it must leave also switch the UV rays and above all it should prevent that the printing object sticks in the bottom of the same. For this reason on the bottom, it must be put a product that separates the bottom from the printing object.

Normally it can be used a product that by osmosis withholds the oxygen, which prevents the resin sticking on bottom of vat. Because, with time and the use, this thin layer deteriorates, it must be changed often.

The solutions adopted by the various manufacturers are:

- PDMS (polydimethylsiloxane) – SYLGARD® 184 – formed from two components to be mixed in the correct proportions at the time of use (solution inconvenient and costly, since the mixing must take place under vacuum for the presence of numerous bubbles inside, besides the fact that must be poured into the vat just the right amount to avoid having too high a layer. It must then be inserted in a perfectly flat oven (using bubble level) to avoid that there is discontinuity of the surface thickness and it must remain in the oven at 60 °C for at least 30 minutes, since in free air the cure time at 25 °C would exceed abundantly 24 hours.

- Replacement of the entire vat (practical solution, but very expensive, the cost can easily reach hundreds of euro for the printers of the most famous brands)

- Siligel sheet of special silicone – replacement is easily and quickly, it is a practical and inexpensive (developed by us)

- FEP (thermoplastic fluoropolymer film) – only recently adopted – still experimental solution.

- CLIP Technology – new technology with technologically advanced material (currently yet it is not commercially available)

- Z Axis

Given that the layers to be printed involve very thin thicknesses, and given the problematic of vat, relative to suction effect, the mechanical structure of the Z axis must be particularly robust, stable and precise, that is, free of any vibration and game, both longitudinal that transversal.

Also, last but not least, the Z axis is to be engineered in such a way which permits the operator to easily reach the base of construction, which in turn must be easily removable for cleaning.

In addition to the strength and the rigidity, there are two other key parts in the Z axis that substantially differentiate the various printers, the sliding guides that are to enable the precise and fluid movement of the head, the screw that must transform the turning movement of the motor in translational movement of the head, zero backlash, without vibration and as accurately as possible.

-

Guide

As regards the guides, also in this case, the choice of manufacturers are the most various, but substantially we will consider only the following two types:

- Prismatic guides – temperate with ball bearing carriages

- Tempered steel bars – with bushings made of thermoplastic material, or with self-lubricating sintered bronze bushes or with ball bearing coupling.

Surely, according to just said, the prismatic guides tempered with recirculating ball carriages, zero backlash, should be preferred to others, because much more rigid, both to longitudinal and transverse, as well as the recirculating ball carriages slide much more fluids on the guides themselves.

On the contrary, the tempered steel bars, however these are, with bushings made of thermoplastic material, or with self-lubricating sintered bronze bushes or with ball bearing coupling, they don’t guarantee rigidity, particularly transversely, this is due to their tendency to suppleness (also in case of bars of considerable thickness). Moreover, even the couplings that slide on the bars do not have zero backlash, due to the fact that to allow their sliding may not have too tight tolerances that could obstruct the shifting.

-

Screw

As we said, speaking of the prerogatives of the Z axis, one of the most important moving mechanical parts, of printers, is the screw with its screw-nut (nut).

The choices of the manufacturer, in this case, are oriented between these three types:

- Ball Screws – with nut to one or more principles, zero backlash

- Rolled acme screw or lathed screw – with plastic / bronze nut, with or without backlash

- Standard threaded rod with triangular profile.

These three types differ dramatically between them, they guarantee performance very different the one from others, and even in some cases completely unsuitable for the use, for this reason we will consider only the ball screws with screw-nut, both to one principle, that to multiple principles, these last certainly the most precise ones.

Another mechanical part closely linked to the operation of the screw is its coupling with the motor, usually Stepper motor.

The choices, even in this case, are oriented between three different types:

- Flexible coupling zero backlash

- Rigid coupling

- Belt and pulleys

The Flexible coupling zero backlash is definitely a good choice, if properly sized and positioned, because it guarantees the transmission of motion even in the situation of misalignment screw / motor, in addition to the fact that it does not transmit vibrations.

The rigid coupling, definitely the least expensive among all, has the advantage of being able to transmit the movement definitely without backlash, between the screw and the motor, but it creates great problems in the case of misalignment, even of a slight entity, and especially it creates problems linked to transmission of vibrations the stepper motor.

Among all, where possible, is preferable the transmission via belt and pulley, that in addition to not give the problems upon described, allows to create a movement ratio (or velocity ratio), thus increasing the engine power.

Resolution

One of the features of stereolithographic printers, whether they use the projector, whether they use the laser, which raises doubts and confusion is certainly the interpretation of the resolution, indicated in the technical characteristics of the various producers.

The resolution in the two main categories (those with the projector, using visible light or UV LED, and those with the laser), are not easily comparable each other. In all cases, it is a good thing to distinguish the two types of resolution, the one on the X-Y plane and the one on Z axis.

- Resolution on the axis (Z axis)

While the resolution of the Z axis in all categories is determined by the quality of the components used (see previous paragraphs) for the realization of the mechanical part of the Z axis itself (for example, using an acme screw, it is impossible to reach resolution of order of 0.01 mm, as is often stated in the technical specifications of some manufacturers, because this value cannot be reached, considering only the backlash of nut on the screw).

Typically, the resolution on the Z axis ranges from 0.01 mm ((10 µm) to 0.1 mm (100 µm).

Note however that in order to make a proper comparison, the resolution of the Z axis (thick layer) impacts heavily on the speed of construction (3D printing). For a correct comparison of the print speeds, account must be taken of the resolution adopted on the Z axis, that is, it is neither right nor consistent, compare printers that work at 50 µm resolution with others that work at 100 µm and more, that will be certainly two / or more times faster than the first (because the adopted layer is more high).

- Resolution on the X-Y plane

The X-Y resolution is directly related to the type of light source used and in the case of a projector, both to visible light that UV LED, the native resolution of this as well as the print size to be obtained and the luminous energy that this allows.

Using a good projector with a native resolution of 1920 x 1080 with 3000 ANSI lumens (lamp power 210W), defining a resolution of 50 µ (0.05mm), to find the print size you should use this formula:

0,05 * 1920 = 96 mm

0,05 * 1080 = 54 mm

That is, with a projector with a native resolution of 1920 x 1080 if you want a resolution of 50 µ you will have a usable size of 96mm x 54mm.

You have also to take in account of the lens focal length to allow positioning the projector as close as possible to the vat of the resin to transmit the maximum light energy and to contain the size of the printer.

This makes it clear that only using projectors of high cost and quality are obtained dimensional characteristics of relief.

In the case of a light source LASER the resolution depends on the diameter of the laser beam and on the quality of the components used for the movement of the laser beam.

The two light sources, projector and laser beam, as above mentioned, are difficult to compare, especially in relation to the different speed of construction, since the laser builds for points while the projector for images.

Engineering solutions

Another very important factor in evaluating a stereo lithography printer, are the construction solutions adopted to determine their durability, usability and accuracy, which define in fact the quality of the printed object.

- Protective cover

The specific function of the protective cover it is substantially different between visible light and UV LED / Laser.

With the illumination source to visible light, the cover helps to protect the resin so that any lights present in the environment can not interfere in the phases of printing and / or deteriorate the resin itself. So, using a printer with a projector to visible light, if the ambient light allows it, you can print while keeping open the cover, with the advantage of more easily control the processing stages.

With the sources of illumination, Led UV or Laser, the cover instead serves to protect the user from possible emissions of dangerous rays. In this case, for obvious reasons, the system are provided of a block in the case in which one tries to open the cover during the printing phase, with the disadvantage of not having the possibility to easily control the processing stages.

In each case the color of the cover must be suitable for the established use in order to block the frequencies harmful to, both for resin, as for user.

- Type and quality of used components

In the market there are many companies that produce components similar to each other, but with qualitative and functional characteristics very different, of course this affects not a little the price of the individual components and consequently on the final price of the printer.

To have a good functionality, high quality and long life of the printer it is essential to use the best components available in the market.

The solutions adopted by each manufacturer in relation to the type of components and their quality, surely, must be one of the most important variables for choice by the user.

Surely a printer realized with components of poor quality, usable for hobby, will give poor results in terms of quality, resolution and repeatability of the printed product, but above all it will limit in time the functionality and life of the printer itself.

- Design

Certainly one of the parameters of choice that makes it more or less attractive one product rather than another, and perhaps the one for which the most part of users is influenced in the choice, leaving aside all other considerations we have made. What is certain is that the design is definitely not the most important parameter. A printer can have a very nice design, but this does not guarantee in any way that it has a well designed structure, which uses high-quality components, that the mechanics enabling it to have good precision, high resolution and durability. Furthermore, in the choice of a printer, it should always take into account the cost of the same – performance ratio and, most importantly, the price of consumables which in some cases can reach exorbitant costs and finally, not in order of importance, the quality of service (assistance) to which we can turn in case, when the printer is purchased, it will present problems.

Warranty and EC Declaration

Another important feature to be considered for a proper choice (especially if the purchase is made for professional uses) is the guarantee and certify that the manufacturer can make about their products.

The guarantee must be a main index of evaluation, considering the fact that only a printer made with expertise and with excellent components can allow the manufacturer to provide long warranty periods and certify their products accordance with regulations in force.

Many times the guarantee becomes a system to post a lower price, in fact many manufacturers offer warranty only for a minimum period (usually the minimum to apply the law), and this obviously allows them to exhibit an initial price much lower, and then, past the warranty period, put the customer in a position to extend, at great cost, the same for a longer period.

To be considered, also, that many manufacturers do not give guarantee (this happens certainly in the case of products supplied in kit), neither the certification.

Assistance and Documentation

Once purchased the printer, it’s possible that, despite its perfect functioning, you are not able to use it, because the documentation is inadequate, or because it lacks assistance by the seller or, worse, by the manufacturer. This is a situation in which you have made a wrong purchase…

Task of a professional manufacturer and prepared is to draw up a clear documentation, detailed and easy to follow as much as possible to allow the user to achieve the purpose for which he made the purchase, and above all, the manufacturer must provide assistance when the need and, if the purchase was made for professional use, in the shortest time possible.

Accessories supplied with machine

Often, to hide the final price of the printer, this is sold with very few or no accessories, requiring the purchaser to a subsequent expenditure is sometimes very costly.

You should be aware that to use properly a 3D stereo lithography printer, this is of any type, you must have accessories.

The process requires that the printer is level (bubble), to manipulate objects with plastic tweezers, to wear disposable gloves, to use a metal spatula to detach the piece from the support. Then, after printing, the piece must be perfectly washed with isopropyl alcohol in an ultrasonic bath, and then the part must be dried perfectly, and the solidification of the resin must be terminated in a UV oven.

In addition to the printing stage, it is very important also the step of cleaning the printer, this requires a series of additional accessories.

The must-have kit to clean the printer is: a container to pour the residual resin (it is strongly recommended to not pour the resin already used in the original container), a plastic spatula for easy cleaning of the vat and for not to ruin the bottom, a brush for the cleaning of the accessories and the vat, a polypropylene container for the cleaning of the tools, a pack of wipes moistened for cleaning the optics of the projector.

Often these accessories can achieve costs that are close to a few thousand euro, which is why they can do the price difference between a producer and another.

Prices of consumables and spare parts

The final price of the printer is not always the thing that differentiates one product from another, because to run a 3D printer uses stereo lithography resin and also as a consumable part of the vat (bottom), then we must also pay attention to the price of these components.

For example, today you can buy inkjet printer to print documents, at a price of less than € 50.00 but unfortunately we realize of the deception when we have to buy replacement cartridges which can cost up to 3 times the price of the printer itself.

In case of the stereo lithography printer, relatively to the resin, you can reach prices above € 400.00 per kg. While relatively to the vat of resin, for some models of printers, the user have to change periodically the vat (completely), in this case it is possible coming to spend over € 300.00 for each change. It is a good thing to pay much attention at the time of purchase, also to this small detail.

Management program

- Open Source (Free software)

Many manufacturers of 3D printers to produce them decide to save money and reduce the final cost of the printer to supply, with the same, a management program of the public domain (that can be used without restriction), surely one of the most widely used of these programs is ‘Creation Workshop’.

Normally for programs of the public domain, by own nature, the user cannot have timely assistance and often they are not stable versions for use, so one uses at own risk.

The choice of programs in the public domain, can be a risky choice because, as has happened with Creation Workshop, after a first period in which the program sources were available (open source), it happened that the author decided not to make them more available, more seriously, in recent weeks, given the success, the author has sold the software to another company that now provides the software in closed form and the payment of a license (for the truth at great cost).

- Proprietary software (No open source)

The Proprietary software is certainly much more costly for the manufacturer, but in this case the user is guaranteed in the time, both for periodic updates that for any modification requested by the users themselves (when possible).

The fact that software has developed specifically for the specific printer, it assures the best possible operation of the printer itself.

Conclusions

Before to buy a stereo lithographic 3D printer, it would be better to ask himself these questions:

The first question

What we have to do with this printer?

- Hobby use – the most important parameter will be the low price at the expense of quality

- Prosumer use – the most important parameter will be the quality at a middle low price

- Professional use – the most important parameter will be the quality regardless of price

The second question

Which light source choose?

- High-pressure lamps – the printers of this typology occupy more space, have high speed and large printing area, but require little maintenance *

- UV LEDs – the printers of this typology occupy little space, have high speed and smaller printing area and minimum required maintenance*

- Laser diodes – the printers of this typology occupy small space, have low speed but a good size of printing area, but require a lot of maintenance *

* Maintenance understood regardless the tank issues.

The third question

What type of projection?

- Projection from top – that is, the light source is located above the resin. This type is surely the less expensive, but it uses more resin and it can have very high cost, given the amount required

- Projection from bottom – that is, the light source is located below the resin. This type is surely more expensive than the previous one, but requires little resin.

The fourth question

What resolution X-Y it must have?

- Low resolution – using a X-Y resolution about 150 µ, it cannot print objects with very thin and very detailed particulars

- Middle resolution – using a X-Y resolution between 80 μ and 150 μ it cannot print objects with very thin particulars, but it will allow you to print objects with very detailed particulars

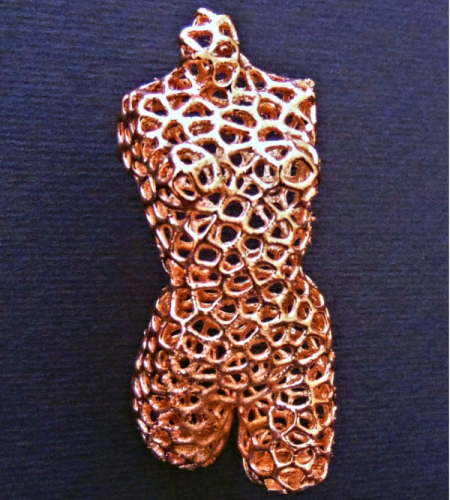

- High resolution – using an X-Y resolution between 20 μ and 80 μ it can print objects with very thin and very detailed particulars. Surely this must be the choice for professional use.

As regards the resolution of Z axis, more it approaches the 100 μ, more the producer will highlight the speed of the own printer. For a correct comparison, the comparison must be made between the various printers with equal resolution (we advise 50 µ).

We also recommend to carefully check the quality of the structure of the Z axis, before making any other consideration.

The fifth question

What construction features have been implemented?

- Protection cover – Do not overlook this aspect that may seem only an aesthetic factor, but instead must protect the user from serious harms, or resin from premature aging

- Type and quality of the used components – Remember that the quality components have a high cost, but guarantee the precision and an long the life of the printer

- Design – this is certainly the most attractive characteristic, but also that often it can be misleading.

The sixth question

There are warranty and EC certification?

One of the cost items which a manufacturer has, it is the management of the warranty and the product certification.

- Without warranty nor EC certification – surely the price will be lower, but if it will happen any unwanted inconvenience, you can wind up with an unusable printer, losing your investment

- With warranty and EC certification – the price of the printer may be higher, but in case of issues you will have the certainty to receive a solution and, in the case of professional use, it will be possible to safeguard your own investment.

The seventh question

Which and how many accessories are supplied with the printer?

3D printing requires a lot of accessories, if you do not receive these with printer, the price will be very low, but remember these can cost a lot and in some cases even to exceed the cost of the printer

- Without accessories – to contain the price they are not included in the purchase, but they are necessary and in some cases they are indispensable

- With some accessories – many manufacturers, to offer their products and convince buyers with a more attractive price, they supply in purchase mini-kits containing only the cheaper accessories. Attention, some indispensable accessories, not included in the purchase, can be very expensive

- With all accessories – Once purchased the printer, you have the warranty to start using it right away (no extra charge).

The eighth question

What will be the price of consumables and spare parts?

This is perhaps a question that few make, but perhaps is one of the most important, since it can significantly affect the actual cost, when you start to use the printer.

- It works only with proprietary resin – this choice is without doubt the most risky and expensive

- It also works with other types of resins – in this way there is the possibility to choose in the market the resin type best suited to own work and with more competitive cost being equal quality

- Any spare parts are readily available – you can be sure in this case that there will be no downtime

- Spare parts are very expensive – this may affect the printer amortization costs

- In case of failure it is necessary the intervention of a technician – this may be another unforeseen item of expense, sometimes very significant.

The ninth question

Which management program is supplied with the printer?

In order to use the printer, you need a program that allows you to manage your own designs, to place them in the plan of printing and to print them.

- Free software – Open source – it allows to pay less the printer, but on it the supplier of your printer does not guarantee assistance, updates, and especially the availability over time

- Proprietary software – Closed source – It affects the cost of the printer, but if you have problems you can have a timely solution to any malfunctioning and you can also take advantage of future upgrades.

The tenth question

Who is the reference of manufacturer, at whom I can turn to for the assistance?

Although the operation of a stereo lithography 3D printer is quite simple, in the initial stage you may need technical support for start-up

- Reseller – verify that he is ready on strengths and weaknesses of the printer, who knows the competitors and that he can use the printer correctly and currently (possibly ask a demonstration)

- Distributor – verify if he has a warehouse with at least some printers and especially if he has available spare parts and consumables, and if he will be available for any technical assistance. Attention, many resellers present themselves as distributors, but in many cases are just dealer, not too often prepared on the optimal use of the printer (ask for the distributor to the manufacturer)

- Manufacturer – it is not always possible to deal directly with the manufacturer, but this opportunity provides full product knowledge, service timely and fast, the best guarantee.

With these 10 questions and the topics covered, we hope to have done a bit of clarity and that now it is easier for many people to make a fair assessment for the purchase of a stereo lithographic 3D printer.

But above all we hope to have given good informations, so, when you access a website or visit a store, you can be able to understand if the quality and specifications are adequate to the price and especially to the use that you have to make, and therefore to be able to compare printers from different manufacturers, starting from the technical characteristics of the same.

Of course, despite having tried to be as objective as possible, this document is certainly not exhaustive, but meant to be only a starting point.

For this reason, we ask readers to help us to expand it with suggestion, to correct it (if necessary), to make it a guide for those, who are not yet skilled or documented on this technology, which is already part of our future.

Pingback: How to evaluate a Stereo Lithographic 3D Printers