- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

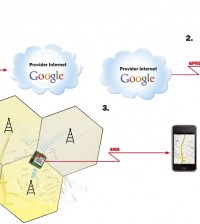

GSM localizer without GPS – Part 6

Assembly

Our localizer is definitely simple, yet it must be built with care, as all of its components are SMD. Once the two-sided board is ready, be sure you have a very fine-pointed welder of up to 20 watts and a 0.02-inch-diametered (possibly, even smaller) welding thread. First of all, take care of the microcontroller; solder a couple of stems opposite one another in order to stabilize it and then solder the rest of the stems. Then go on to the passive components, quartz and transistor. For the GSM/GPRS module, there is a small high-density connector to be soldered on the printed board, possibly with the aid of a magnifying lens to make sure there are no solder “whiskers” short-circuiting neighboring areas . On the mini-module just inserted you can attach and connect the SIM-card holder. Cellular antenna connection involves a triple golden spring contact which, pushing the component all the way into its connector, touches a pad purposely created in one of the corners of the c.s.; there one can solder the antenna cable or, depending on its shape, the antenna itself. For our model, we simply used a thread fragment about 3.15 inches long as an antenna; however, depending on the space available, one can choose a cellular antenna, even a printed-board one. Once everything has been assembled, one can proceed to the in-circuit programming of the microcontroller through the CN1 connector (8 poles). An additional two-pole miniature connector must be mounted for battery connection.

PARTS LIST

R1, R5: 4,7 kohm (0805)

R2: 10 kohm (0805)

R3, R4: 330 ohm (0805)

C1: 100 µF 6,3 VL tantalum (CASE-B)

C2, C3: 100 nF multilayer (0805)

C4, C5: 10 pF ceramic (0805)

C6, C7: 470 µF 6,3 VL tantalum (CASE-X)

U1: PIC18LF6722 (MF833)

LD1: red LED

LD2: green LED

Q1: 20 MHz quartz (12SMX)

T1: BC817

SW1: Slide switch

GSM1: GSM0308

P1: Microswitch 90° SMD

Miscellaneous:

– CS connector 100 pin for GSM

– 8 pole connector 90° 1 mm

– PCB

Download PCB details (Layout and Gerber): PCB