- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

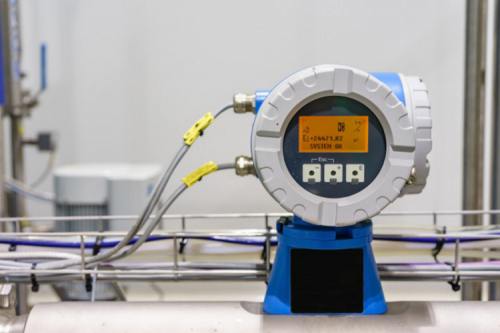

5 Types of Industrial Flowmeter

In an industrial setting, the use of flow meters is highly encouraged as its use can define both profit and loss, and especially the safety of the workers on site. Although there are a lot of flow meters to choose from, the main goal of a flow meter is to measure the flow rate or volumetric flow rate.

Even if they have the same goal in measuring the flow rate of the liquid or gas going through a pipe, every type of flow meter varies in their application. Each of them has its requirements to be met in installation, the difference in how you use them, and their function.

Thus it is essential to know their individuality to make the most of their efficiency and effectiveness in the field. Here are some of the most common flow meters used in different industries and how they are operated.

Differential Flow Meter

The primary function of differential flow meters relies on Bernoulli’s equation. This flow meter presents a constriction that is located within the pipe for it to drop in pressure. Impulse piping will then measure the pressure in both upstream and downstream and calculate the difference in both of them.

More or less 21% of the whole world’s flow meters are differential flow meters as it is more commonly used in the oil and gas industry, chemical, power, waste, mining, paper and pulp, metals, pharmaceutical, beverage, and the HVAC.

Paddle Wheel Flow Meter

Paddle wheel flow meters come in different shapes and sizes. The most common among them comes in the form of oscillating disks, rotating paddle wheels, and propellers. As the fluid goes in the pipe and through the paddle wheel flow meter, the rotation of the propeller will generate a pulse. The frequency of the pulse is proportional to the velocity of the fluid that is going through at any point in the pipe.

Although it sounds complicated, it is quite easy to understand. Also, it comes with high precision and accuracy, albeit the low cost. This is the main reason why it is most prevalent in rural areas for the use of irrigation, water, and waste management. Paddle wheel flow meters are even capable of measuring the flow rate of a viscous liquid in high pressure, which makes it commonly used in the oil and gas industry or any other industry that deals with contaminated water.

Positive Displacement Flow Meter

Speaking of viscous fluids, one such flow meter called positive displacement flow meter are designed and built to measure the flow rate of any contaminated fluid. As the liquid goes in the pipe and though the positive displacement flow meter, it entraps the liquid and measures its volumetric rate.

Because of this, positive displacement flow meters are ideal for measuring the flow rate of viscous liquid such as paint, adhesive, petrochemicals, etc. There are advantages in using positive displacement flow meters such as high precision, operational even with little human assistance, low cost, and longevity.

This type of flow meter is more commonly used in power, chemical, oil and gas, food processing, and pharmaceutical industry. Also, there are several subtypes of positive displacement flow meters, such as rotary vane, nutating disks, oval gear, and reciprocating pistons.

Magnetic Flow Meter

Magnetic flowmeters come in two forms, namely, full-bore and insertion. Magnetic flow meters, by the use of electrical coils, develops a magnetic field that will measure the voltage generated by the fluid. Thus, magnetic flow meters are most efficient in measuring highly conductive material. By the use of an electrode in the wall or with the use of an insertion probe, the conductive fluid will pass through the magnetic field and will generate a voltage that is proportional to the volumetric flow.

However, magnetic flowmeters should not be used to measure the flow rate of any non-conductive fluid, such as deionized water. Magnetic flow meters are usually used in a lot of industries like oil and gas, paper and pulp, food processing, chemical manufacturing, etc.

Mass Flow Meters

Mass flow meters, or sometimes called inertia flow meters, measures the flow rate of a fluid by allowing the liquid to pass through a tube. The calculations are made by measuring the mass of fluid passing a static point per time.

This type of flow meter is mostly used in mass-related processes, thus the name. This is because of its highly efficient ability to measure the force that results from the speeding of the mass. Also, there are two types of mass flow meters: Coriolis mass flow meter and thermal dispersion flow meter.

Takeaway

Although the flow meters mentioned above greatly vary from each other, most of them are highly adept in a lot of industries such as oil and gas, power, agriculture, and mining. They may have the same goal of measuring the flow rate of liquids; each of them has their advantage over the other with their difference in application. Also, there are a lot of places on the internet that deal with different flow meters. Market prices are available such as mass flow meter price and vortex flow meter price.

Author’s Bio:

Sylvia Hopkins is a writer and a blogger, specializing in topics like flow measurement technology. When not working, Sylvia pampers herself at the spa and salon.