- makeITcircular 2024 content launched – Part of Maker Faire Rome 2024Posted 2 weeks ago

- Application For Maker Faire Rome 2024: Deadline June 20thPosted 2 months ago

- Building a 3D Digital Clock with ArduinoPosted 7 months ago

- Creating a controller for Minecraft with realistic body movements using ArduinoPosted 7 months ago

- Snowflake with ArduinoPosted 8 months ago

- Holographic Christmas TreePosted 8 months ago

- Segstick: Build Your Own Self-Balancing Vehicle in Just 2 Days with ArduinoPosted 8 months ago

- ZSWatch: An Open-Source Smartwatch Project Based on the Zephyr Operating SystemPosted 9 months ago

- What is IoT and which devices to usePosted 9 months ago

- Maker Faire Rome Unveils Thrilling “Padel Smash Future” Pavilion for Sports EnthusiastsPosted 10 months ago

3Drag (or Being Open Source, For real)

Being really open source is no joke. Open sourcing an hardware product, usually goes through several major steps. The first one is usually verifying that all the software is really open source, Free to use and adapt and accessible. It’s very important to stress this point, there’s a big difference in freeware (and in general software that is free to use) and Free software (software that grants some important Freedoms).

Unfortunately, many good softwares – for example some of the most handy modeling software – such as Google Sketchup – are free to use (at least some variants) but not Free softwares.

Even if this could seem a little difference you should think of the problems that may arise from a free-to-use software that disappears from the market.

Let’s say that you designed your machine using a Software Package and at some point the new version of this gives no more free access and it’s available only for purchase: you may be lucky having a saved version of the product and you may continue working with it but that’s not the case for everyone. This problem it’s even more important if you think to the so called to Software As A Service solutions: these may disappear overnight and the features change continuously making it difficult also to share instructions.

The second aspect regards the hardware designs: it’s very important that these designs are available in a reasonably open format (this reverts back to the discussion about the tools in some way), that doesn’t require licenses or very expensive programs to be accessed and modified. That’s why our designs are available in the DXF format that you can open and access.

The second aspect regards the hardware designs: it’s very important that these designs are available in a reasonably open format (this reverts back to the discussion about the tools in some way), that doesn’t require licenses or very expensive programs to be accessed and modified. That’s why our designs are available in the DXF format that you can open and access.

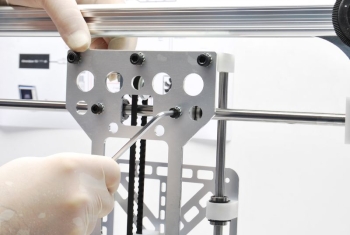

Last but (absolutely) not least, the entire process for building the machine should be completely clear and accessible. That’s why, in the last few weeks, we spent a lot of time in translating and preparing an accurate guideline.

Those of you that are more interested in how OSHW is defined and what is the definition of it, shall look into the Opens Source Hardware Definitions that the OSHWA put together, available here: http://www.oshwa.org/definition/

This definition covers twelve points and is by far, the most comprehensive analysis we have so far, you’re fairly encouraged to use it when you call your project Open Source Hardware.

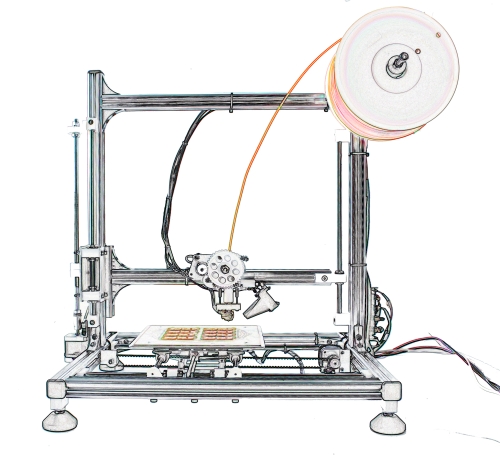

The 3Drag construction process entirely available on RepRap wiki right now, with a so detailed building process that is probably the most documented (hundreds of pictures , step by step guides) so far on that wiki. We believe that a step by step guide was pretty crucial of course for those that bought our kit that need to mount the machine but also for makers and hackers interested in building the 3Drag on their own or, maybe, in modifying it.

The 3Drag construction process entirely available on RepRap wiki right now, with a so detailed building process that is probably the most documented (hundreds of pictures , step by step guides) so far on that wiki. We believe that a step by step guide was pretty crucial of course for those that bought our kit that need to mount the machine but also for makers and hackers interested in building the 3Drag on their own or, maybe, in modifying it.

It’s interesting to note, in fact, that having access to the construction plans will allow people to use part of the 3Drag to eventually make new machines, copy and improve technical solutions, and more.

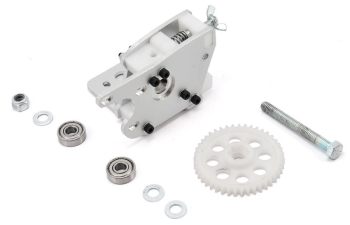

You can obviously find all the sources to cut the aluminum profile parts, as well as the measures of the rods, washers, nuts, geared parts and all the general purpose materials needed to build the machine with a complete Bill Of Materials.

Also the 3Drag controller is completely open source. In fact you can find all the designs and components to make it on this blog, or on the RepRap Wiki.

On the software side, as we explained greatly here in this post here , all the components used are fully open source (both the original Marlin firmware and our improvements) and this actually makes our machine a genuinely open, accessible, powerful 3D printer.

Unfortunately, this is not enough to make a lively and collaborative open source project, and that’s our objective after all, as we don’t want simply the 3Drag to be open source per se: instead we want a community of makers and hackers to experiment with our 3D Printer design and constructive choices…

Our dream would be to see people iterate on the 3Drag project with new solutions: would you add another extruder? Why don’t you add CNC milling features? Would you change the materials? Find a clever solution to improve the machine in some of its outstanding limitations? Do you want to make a giant one and print your house?

Our dream would be to see people iterate on the 3Drag project with new solutions: would you add another extruder? Why don’t you add CNC milling features? Would you change the materials? Find a clever solution to improve the machine in some of its outstanding limitations? Do you want to make a giant one and print your house?

The nice thing is that now you can do that. Another nice thing is that we are here to get your feedbacks, ideas and tricks and incorporate those in the machine, giving you all the credits and publishing your work to the community.

It will be particularly interesting to know how do you feel using the machine, what kind of modifications are you planning to put in place to improve the performances: these kind of improvements can only emerge from the user base. In fact, is the variety of different usage scenarios of the printer, the variety of printed objects and use cases that can only come from the user base that will end up in showing printer limitations, problems and potential improvement directions.

We want to build a great 3D printer, that is strongly inspired to community feedback: I would say that the people developing this amazing machine are really committed to “design the 3D printer that community wants” starting from some radical and well tested construction choices

Pingback: Maker Faire Rome Premiere: presenting Open Wheels | Open Electronics