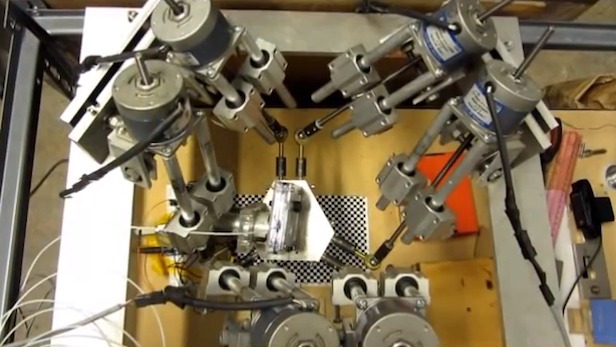

According to 3Ders (http://www.3ders.org/articles/20131006-6-axis-3d-printer.html) this video shows preliminary works for a 6-axis 3D Printer using Parallel Kinematics driven by a KFLOP board

Most additive manufacturing processes are layer-based with only three-dimensional motions in the X, Y and Z axes. However, there are drawbacks associated with such limited motions, e.g. non-conformal material properties, stair-stepping effect, and limitations on building around inserts. Such drawbacks limit the applications of additive manufacturing in many areas. To enable 6-axis motions between a tool and a work piece, we investigated a Stewart mechanism and developed a low-cost prototype system for multi-directional additive manufacturing including the Fused Deposition Modeling and CNC accumulation processes. The technical challenges in our development are the hardware design, coordinate transformation, platform constraint checking, movement simulation, tool path generation, and part fabrication. Several test cases are also presented to illustrate the capability of multi-directional additive manufacturing processes.

ia ▶ 6-axis 3D Printer – YouTube.