Nixie tubes are completely outdated, but they still look very cool, which is why makers like to use them to build decorative clocks. Nixie tubes can also be used to display other kinds of information, and this filadometer project is evidence of it.

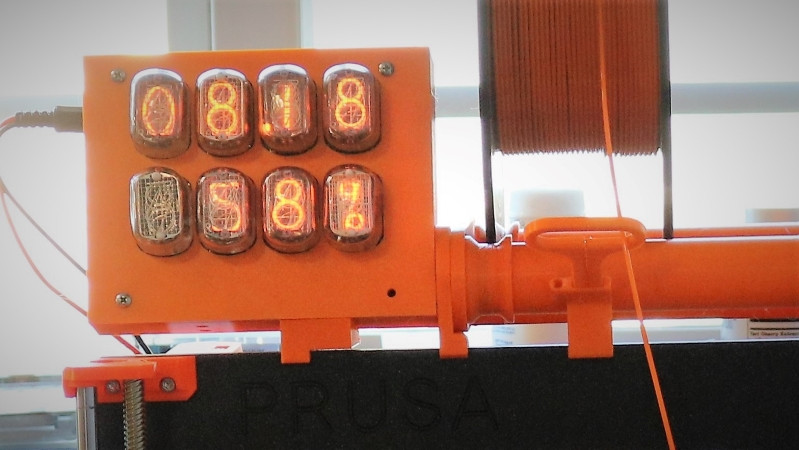

The maker decided to recycle his old temperature/humidity eight-tube display to keep track of his Prusa. The filadometer sits on top of his 3D printer, an Original Prusa i3, and displays how many meters of filament have been used and the completion percentage of the print job on seven IN-12 and one IN-15 Nixie tubes.

Those are connected to a custom PCB, which includes a header to mate with a Raspberry Pi Zero W. The Raspberry Pi pulls the filament data from OctoPrint, which is running on a second Raspberry Pi that’s connected to the 3D printer.

“First, I decided to upgrade from the Raspberry Pi Model B to a more recent Raspberry Pi Zero W that I had on hand. Wired Ethernet is so ~ 2013 after all, and wireless would be a lot more convenient. Next, I designed a 3D printed case for it, as my old laser-cut-acrylic-and-glue case also looked very dated. Finally, I replaced the software with a new program designed to poll the data from my octoprint server. In less than an afternoon, I had turned the old temperature/humidity display into something useful.”

The video below shows the details.